Application of open plant foam cleaning machine in food factories

The cleaning and sanitation of open areas within the factory are crucial. These vast unenclosed spaces, including production workshops,

packaging areas and storage facilities, are the backbone of any successful food manufacturing operation. Neglecting proper cleaning and

disinfection of these critical areas can have far-reaching consequences, jeopardizing food safety, product quality and overall operational

efficiency.

Food safety regulations, such as the BRC Global Standard, require food manufacturers to maintain the highest levels of cleanliness and

sanitation throughout their facilities. Complying with these guidelines not only protects consumers, but also safeguards the factory's ability to

continue to operate and supply products to the market. Proactively cleaning and disinfecting open areas demonstrates that food factories are

committed to complying with regulations and are committed to maintaining the highest food safety standards.

In the fast-paced world of food production, efficiency and efficacy are the cornerstones of a successful sanitation program. Recognizing this,

WONE has developed advanced foam cleaning machines that seamlessly integrate three basic functions(high pressure washing, foaming

and disinfection) into a comprehensive solution.

03

Foam cleaning machine is widely used in the food industry, including meat processing plants, baking industry, dairy processing plants,

seafood processing plants, wine processing plants, poultry processing plants, central kitchens, fruit and vegetable processing, fried food

plants, candy processing plants.

Here, we are going to list the facilities and equipment of food factories that foam cleaning machine is suitable for

1. Equipment and facilities with many vertical facades

- For example, rolling kneading machines, mixing barrels, sauce tanks, meat carts, beaters, walls and other deep surfaces

- Fully cleaned by hanging foam on the wall, the foam can adhere to the vertical and top surfaces, enhancing the cleaning anddisinfection effect.

2. Irregular cleaning surface

- For example, propeller machines, conveyor belts, mesh structures, etc.

- The permeability of the foam ensures that all surfaces are fully covered.

3. Removable pipes and elbows

- The foam can penetrate into narrow passages and complex pipe geometries, adhere to the entire pipe surface, and fully clean.

4. Equipment with heavy grease and heavy dirt

- For example, smokers, fryers, ovens

- Foam makes the degreasing effect more significant

5. Large areas of space

- For example, floors, some conveyor belts, etc.

- Foam can be formed quickly during cleaning and continue to work, with high efficiency

04

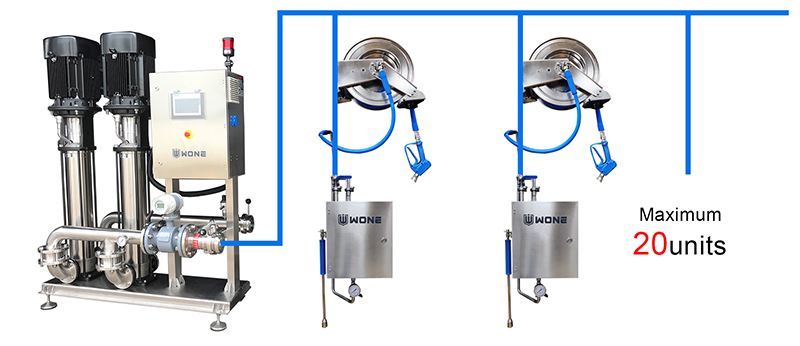

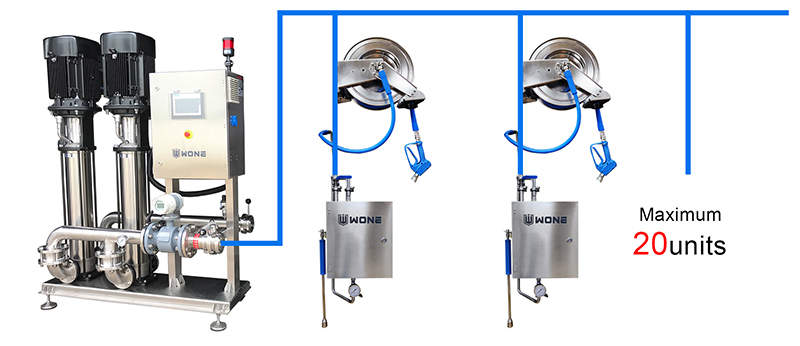

Large food processing facilities often require sturdy, high-capacity foam cleaning systems to effectively deal with extensive production lines,

large storage tanks and complex pipeline networks. These advanced machines use powerful pumps, precise chemical dosage and intuitive

control systems to ensure comprehensive coverage and consistent results across a wide operating area.

On the other hand, smaller workshops or specialized production departments within food factories may benefit from more compact and

mobile foam cleaning units. These flexible solutions enable targeted local cleaning, enable operators to move seamlessly between

workstations, and meet the specific needs of individual equipment or work areas.

We know the different needs of food factories and have developed a range of models and configurations to meet the different requirements

of the industry for different plant sizes, different workshops, multiple plot points in the same workshop, etc. This adaptability enables food

producers to choose the most appropriate cleaning solution, improve their hygiene practices, and ensure product quality and safety.

Let's see what foam cleaning machine we have

01-EFC-325E

- Smart foam cleaning machine

- 25m high pressure hose, can clean anywhere within 25m radius

- suitable for less than 10 cleaning sites in the workshop

-

.jpg)

02-EFC-325M

- Mobile foma cleaning machine

- movable and flexible cleaning range

- suitable for factories with few cleaning points, or cleaning site with intermittent cleaning, or less than 3 cleaning site

-

500宽.jpg)

03-EPW-175

04-EPW-275

For more knowledge about food factory safety and hygiene, welcome to communicate with us.

.jpg)

.jpg)