Boost Efficiency with OPC Foam Cleaning Machines for Food Processing

In the high-stakes world of food processing, maintaining impeccable hygiene is non-negotiable. Contamination risks, regulatory standards,

and consumer expectations demand cleaning solutions that are both thorough and efficient.

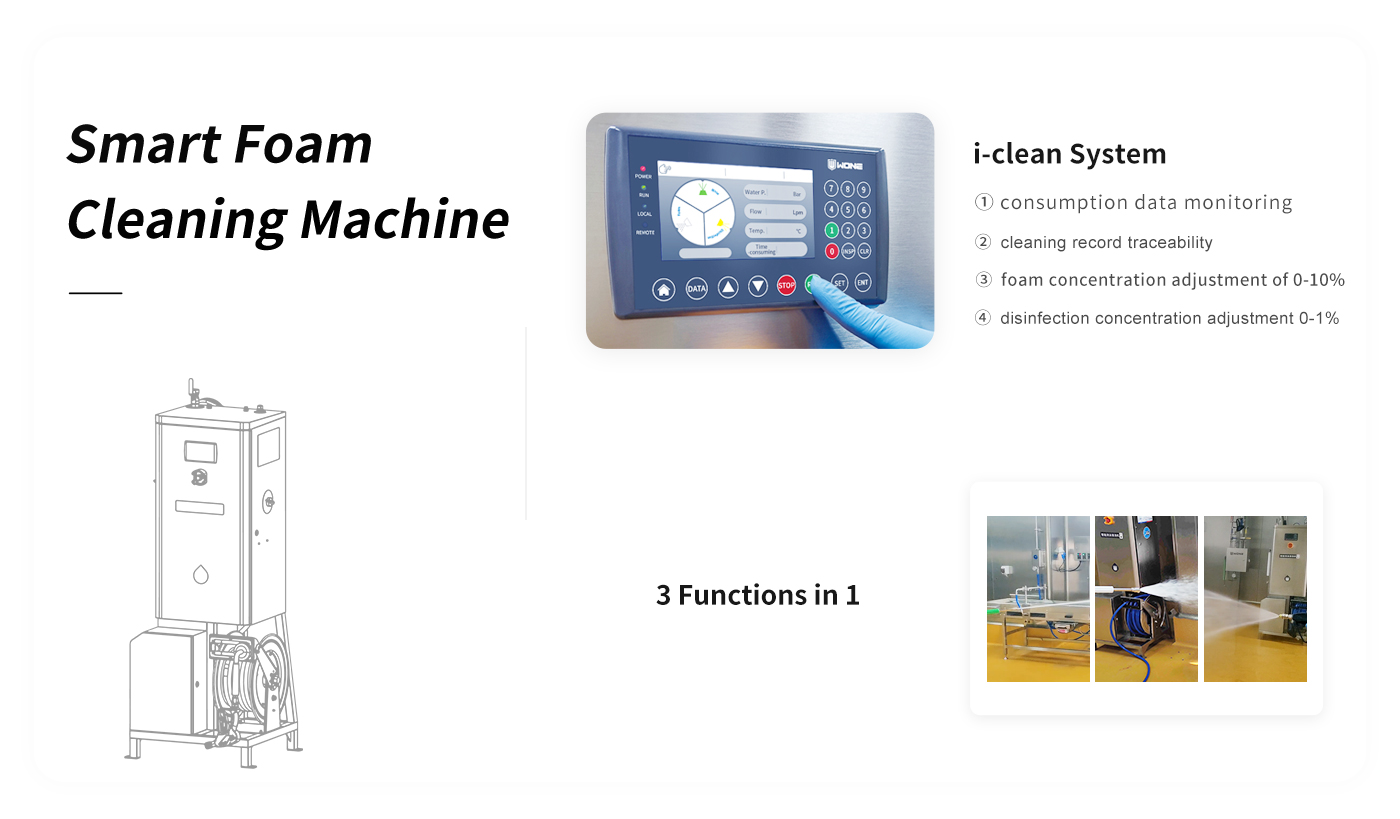

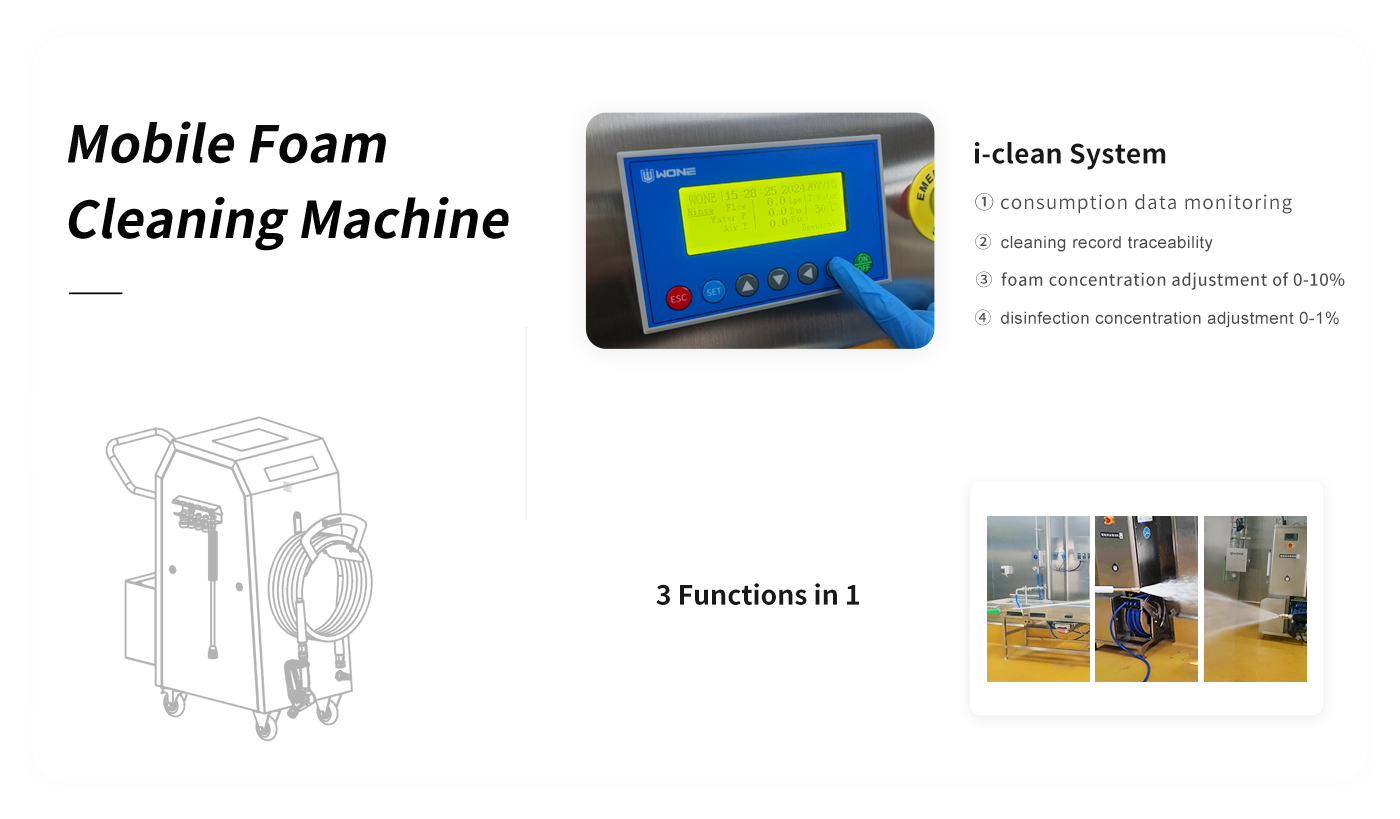

Traditional methods often fall short, consuming excessive time, water, and chemicals while leaving room for human error. Come to the foam

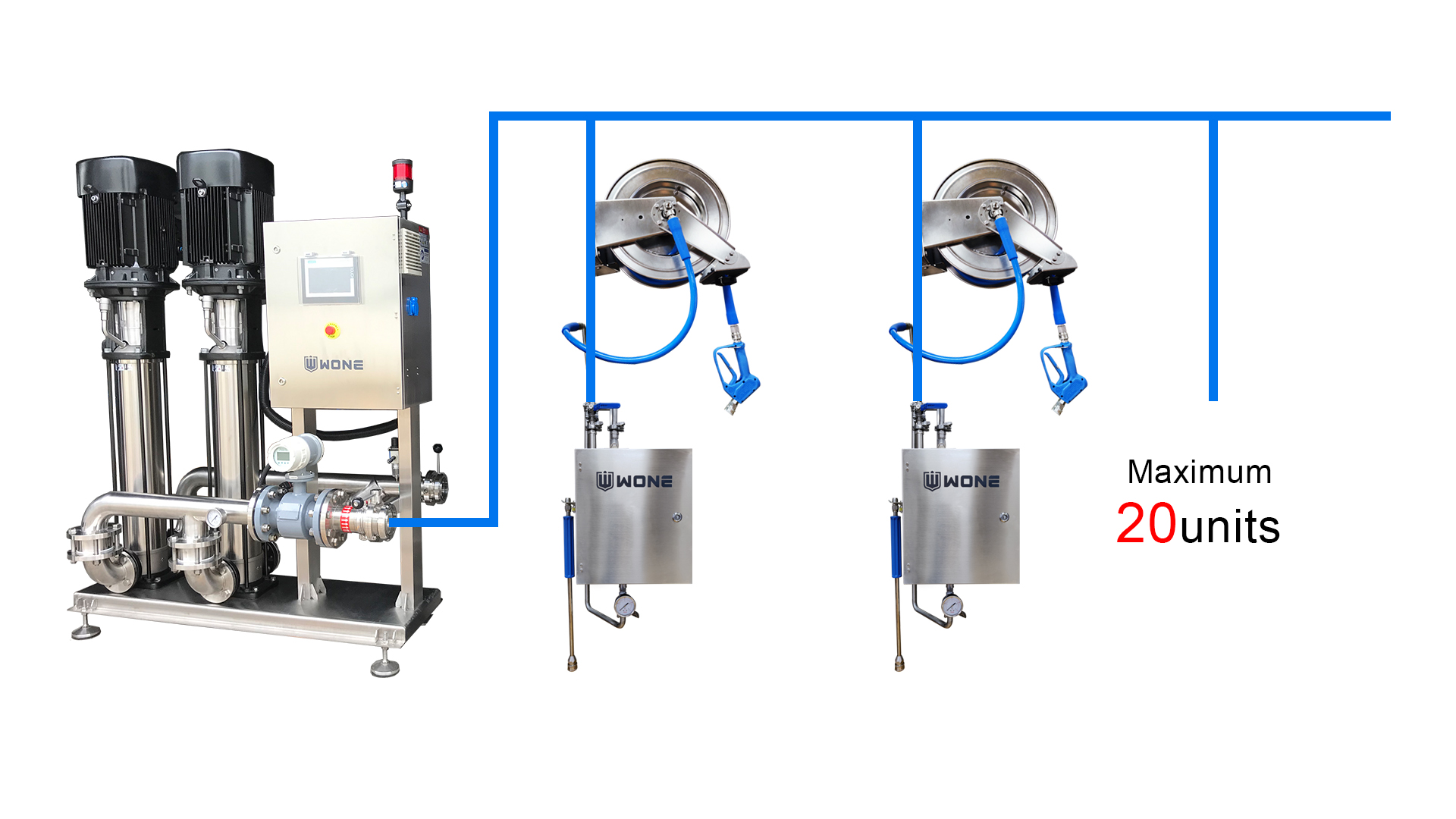

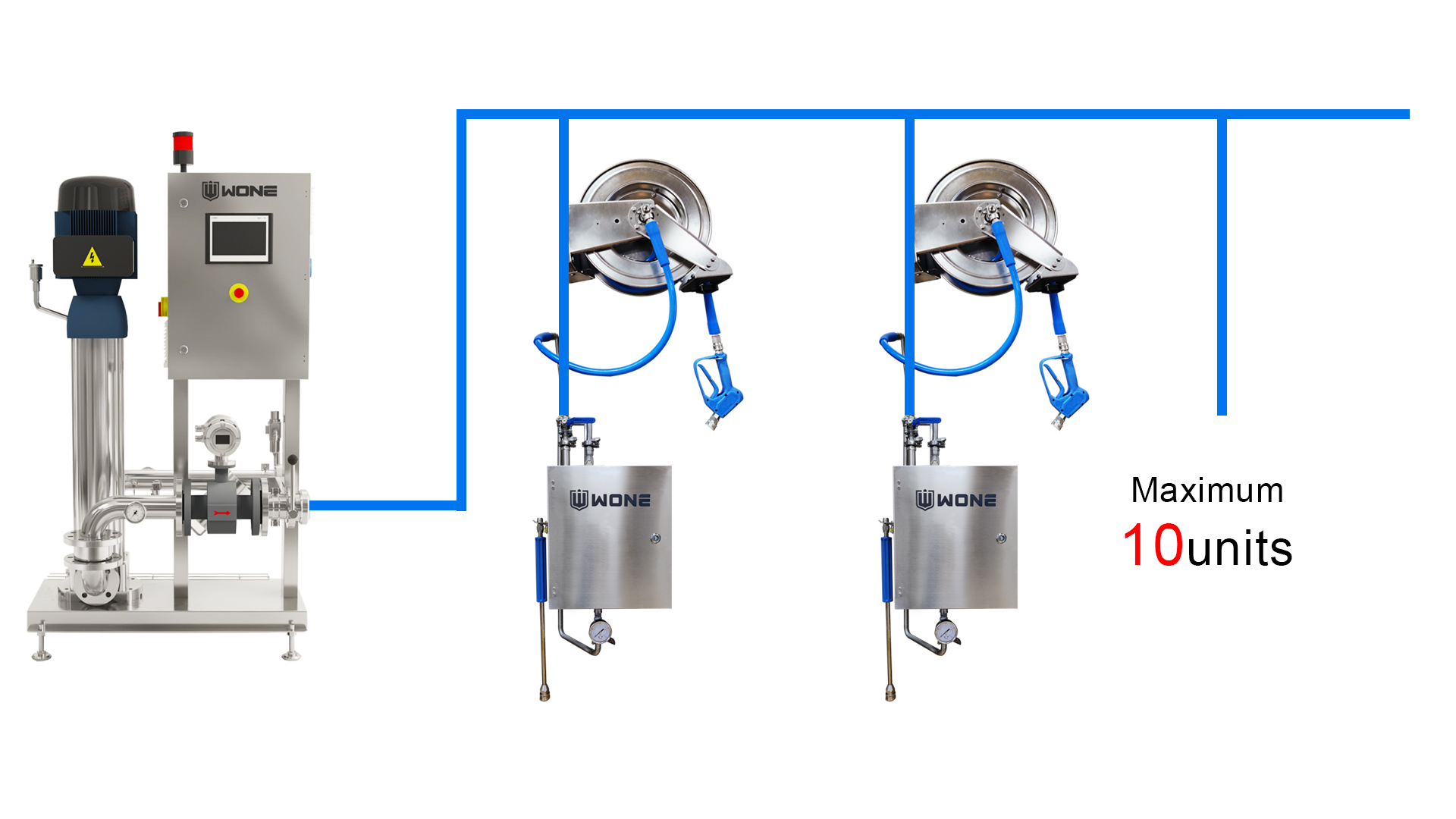

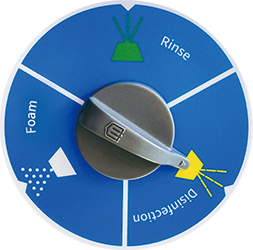

cleaning machine—a technological leap designed to address these challenges head-on. OPC's advanced foam cleaning system integrate

high-pressure rinsing, foaming, and disinfectant spraying into a single machine, revolutionizing how facilities achieve cleanliness. Let's expl-

ores how these machines enhance efficiency, reduce costs, and elevate safety in food processing environments.

The Hygiene Imperative in Food Processing

Food processing facilities operate under relentless pressure to eliminate pathogens, allergens, and residues. Every surface, from conveyor

belts to storage tanks, must undergo rigorous cleaning to meet FDA, USDA, and HACCP standards.

Traditional approaches, such as manual scrubbing or low-pressure hoses, are labor-intensive and inconsistent.

In contrast, a foam cleaning machine delivers precision by generating dense foam that clings to vertical and overhead surfaces, penetrating

crevices where bacteria thrive. The adjustable foam concentration ensures tailored cleaning for light soiling or stubborn grease, making it a

versatile ally in the fight against contamination.

Time Consumption

- Manual cleaning disrupts production schedules, extending downtime.

Water Waste

- High-volume rinsing strains resources and increases utility costs.

Chemical Overuse

- Inconsistent application leads to excessive disinfectant use, risking residue buildup.

Incomplete Sanitation

- Complex machinery often retains hidden contaminants.

OPC's foam cleaning machine tackles these pain points by automating processes. The integration of high-pressure rinsing removes debris

swiftly, while foam application ensures chemicals dwell longer on surfaces for optimal efficacy. By adjusting foam density based on soil seve-

rity, facilities minimize chemical waste without compromising results.

OPC's engineering prowess shines in three core functionalities unified within their foam cleaning machines:

High-Pressure Rinsing:

- A pre-rinse phase blasts away loose debris with high prssure, preparing surfaces for deeper cleaning. This step reduces the workload for subsequent stages, conserving water compared to traditional methods.

-

.png)

_69742.png)

Foam Application:

- The foam cleaning machine converts detergent into thick foam, expanding its surface coverage. Foam's adhesive properties allow it to cling to equipment for 10–15 minutes, dissolving oils and biofilms effectively.

-

.png)

Disinfectant Spraying:

- Post-rinse, a fine mist of food-safe disinfectant is applied, ensuring microbial eradication. The system's programmable settings let users toggle between sanitizers, adapting to specific regulatory or operational needs.

-

Not all stains are created equal. Light residues on packaging lines demand gentle treatment, while hardened grime in grinders requires agg-

ressive action. OPC's foam cleaning machine features adjustable concentration settings, allowing operators to modulate foam density via a

user-friendly interface. Sensors detect soil levels in real-time, automatically calibrating chemical ratios—a boon for facilities handling diverse

products like dairy, meats, or baked goods. This adaptability reduces chemical consumption by up to 30% while ensuring consistent outcom-

es.

Boosting Efficiency: How Foam Cleaning Machines Outperform?

Faster Turnarounds:

- A foam cleaning machine completes tasks in half the time of manual methods. Automated cycles standardize cleaning protocols, cutt-ing downtime from hours to minutes.

Resource Conservation:

- Precise foam targeting slashes water use by 40–60%. Closed-loop systems recycle runoff, aligning with sustainability goals.

Labor Savings:

- Reducing reliance on manual labor mitigates ergonomic risks and reallocates staff to value-added tasks.

Compliance Assurance:

- Digital logs document cleaning parameters (time, chemical ratios, temperature), simplifying audits and traceability.

-

Case Study: Streamlining Poultry Processing

A Midwest poultry plant grappling with Salmonella risks adopted OPC's foam cleaning machines for its evisceration line. Previously, nightly

cleaning took 3 hours using foam guns and hoses. Post-implementation, the automated cycle achieved deeper sanitation in 45 minutes.

ATP swab tests revealed a 99.8% reduction in microbial load, while water bills dropped by 52%. Staff reported easier operation, citing the

machine’s intuitive controls and adjustable foam settings for varying residue levels.

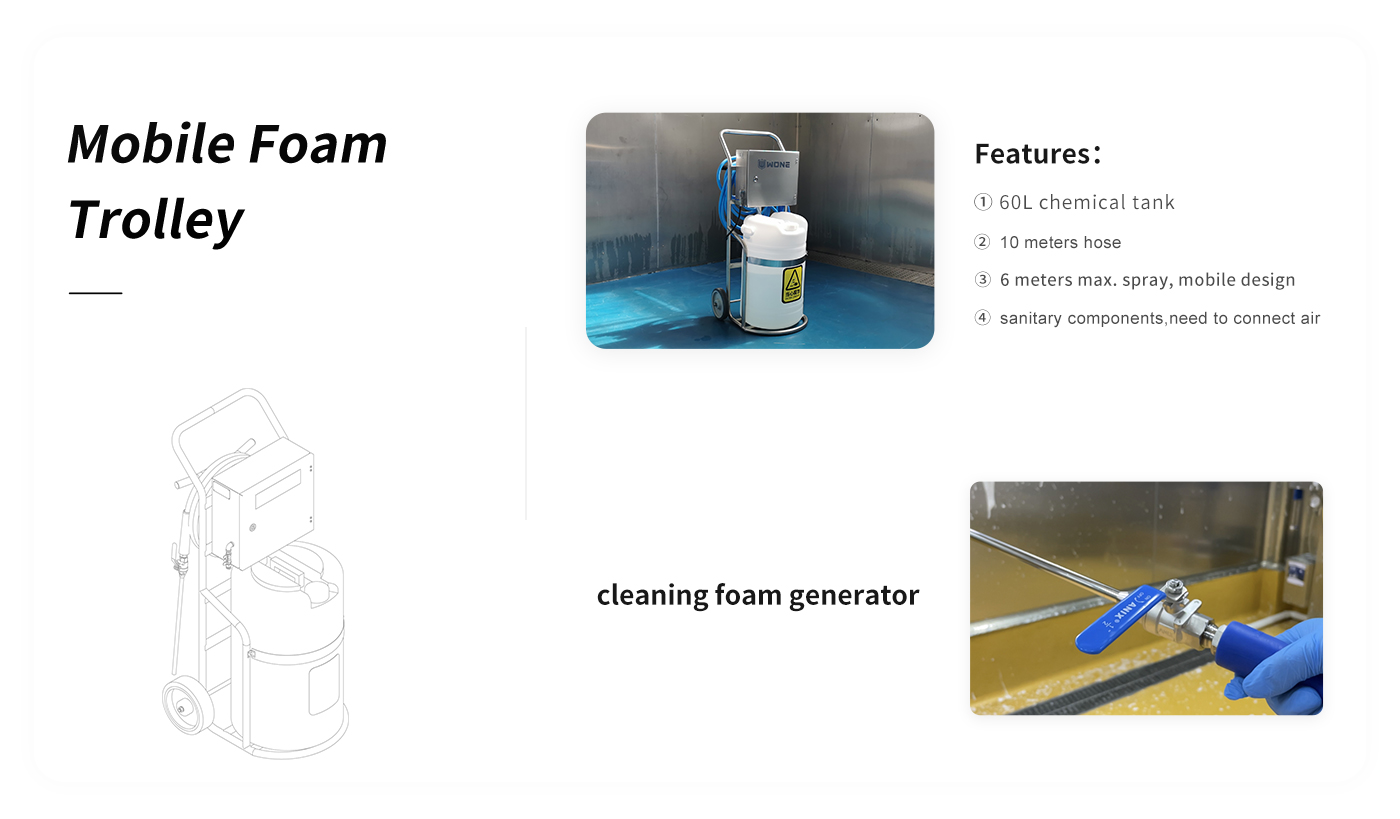

When evaluating foam cleaning machines, consider:

Throughput Needs:

- High-volume facilities may require stationary units, while smaller plants benefit from portable models.

-

拷贝.jpg)

Chemical Compatibility:

- Ensure the machine supports USDA-approved detergents and sanitizers.

Durability:

- 304 Stainless steel construction resists corrosion in wet, acidic environments.

Tech Integration:

- IoT-enabled machines offer remote monitoring and predictive maintenance alerts.

The Future of Food Processing Hygiene

As automation reshapes the industry, foam cleaning machines will become central to smart factories. Innovations like AI-driven soil detection

and self-cleaning nozzles are on the horizon. By adopting OPC’s technology today, processors future-proof their operations while meeting

escalating consumer and regulatory demands.

Conclusion

In an era where efficiency and safety are paramount, OPC’s foam cleaning machines offer a transformative solution for food processors. By

unifying high-pressure rinsing, foaming, and disinfection, these systems slash downtime, conserve resources, and eradicate pathogens with

unmatched precision. As facilities worldwide embrace automation, the foam cleaning machine stands out as a cornerstone of modern hygiene

—proving that innovation and practicality can coexist to safeguard our food supply.

Investing in a foam cleaning machine isn't just about upgrading equipment; it’s about elevating operational standards to thrive in a competitive

, conscientious market.