channel-type hygiene station for food factory workshop entrance

In food processing plants, channel-type integrated personnel sanitation and cleaning station equipment is designed to ensure that employees

are effectively cleaned and disinfected before entering the production area in a food factory. These machines provide a comprehensive

solution for cleaning and disinfecting personnel, minimizing the risk of contamination. The following is an overview of the personnel sanitation

and cleaning solutions provided by these systems.

Compared with traditional disinfection methods, the channel-type integrated machine solution for personnel entry disinfection has the following

significant features:

Improving the disinfection standards for personnel entry

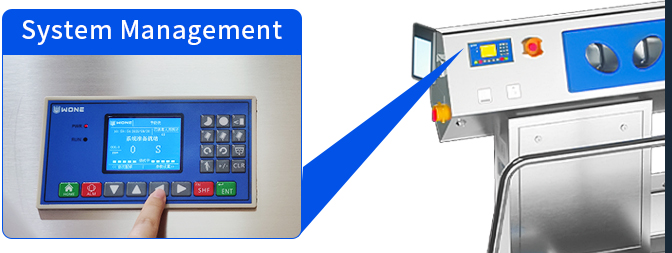

--The equipment has its own disinfection program, that is, the sanitation brain, that is, the i-clean system; different disinfection standards for

different cleaning zones are set.

--The channel-type workstation operation is combined with the gate machine to achieve a one-way flow of personnel disinfection and eliminate

disinfection evasion.

--Complete each step of the disinfection operation according to the mandatory procedure to ensure the standardization and normalization of

everyone's disinfection.

Good disinfection atmosphere for personnel entry

--People flow in one direction according to the channel workstation and disinfection rhythm, without congestion and intersection, and the order of

entry disinfection is good.

--Voice and/or interactive lights guide the disinfection operation, which is both easy and focused when operating.Fast and effective staff disinfection training

--Can be used as a training machine for disinfection training;

--New employees can practice disinfection and assessment on the machine, quickly forming hygiene awareness and habits; greatly reducing

training costs.

Promote food safety performance

-Upgrade traditional disinfection methods to generate new disinfection momentum;

-Improve staff hygiene awareness and ability;

-Show the soft and hard strength of the company's food safety;

-Add points to official/customer evaluations.

- Hand cleaning includes taking soap, washing hands, drying hands, and disinfecting hands; work shoe disinfection; guard

- Mandatory hand cleaning before entering the workshop, mandatory disinfection of hands and work shoes, and narrow workshop entrance

Function:

- Hand cleaning includes taking soap, washing hands, drying hands, and disinfecting hands; work shoe brushing and work shoe disinfection; biological locks include cards and face recognition; guard

- Mandatory hand cleaning before entering the processing area, mandatory brushing of work shoes; mandatory disinfection of hands and work shoes, and narrow workshop entrance

Function:

- Hand cleaning includes hand disinfection; work shoe brushing and work shoe disinfection; biological locks include swiping cards and face recognition; guard

- Mandatory brushing of work shoes before entering the workshop working area; mandatory disinfection of hands and work shoes, and narrow workshop entrance

Function:

- Hand cleaning includes taking soap, washing hands, drying hands, and disinfecting hands; disinfecting work shoes; guard

- Mandatory hand cleaning before entering the production lines, mandatory disinfection of hands and work shoes, narrow workshop entrance, and fewer employees entering the workshop

For more information about food safety and sanitation equipment, please communicate with us.

ed.jpg)

ed.jpg)

ed.jpg)

.jpg)