Cleaning and Disinfection of Food Factories Is Not A Simple Scrubbing and Washing

Biofilms can adhere to solid surfaces or exist at the interface of liquids and air. They are metabolically active complexes composed of micro-

organisms, water, and polysaccharides and proteins secreted by microorganisms. Biofilms are the main form of microbial survival and have

the function of protecting microbial communities in adverse environments.

About biofilms

Bacteria in biofilms are up to 100 times more resistant to antibiotics, hydrogen peroxide, or detergents than free cells. In cleaning and disinf-

ection, biofilms are the focus of attention. The three characteristics of biofilms make them extremely harmful to the food industry:

First, the adhesion of biofilms. Since the polysaccharides in biofilms have strong adhesion to solid surfaces, it is difficult to remove biofilms.

Once biofilms are formed, it is difficult to remove them with a simple cleaning and disinfection process. Professional formula cleaners must

be used in accordance with appropriate cleaning and disinfection procedures to remove them.

Second, the anti-disinfection characteristics of biofilms. Bacterial cells in biofilms are more resistant to disinfectants than planktonic bacteria.

Third, biofilms can cause biological deposition, thereby corroding equipment and affecting heat conduction efficiency.

In order to ensure food safety, we need to clean and disinfect the processing equipment and environment every day. Cleaning is not

only to remove food dirt, but also to dissolve polysaccharides and other substances on the biofilm from the solid surface, and then kill the

residual microorganisms after cleaning through disinfection. Most food processing environments are still open environments, and it is impos-

sible to achieve a completely sterile state. Some parts will be temporarily sterile after cleaning and disinfection, but as long as there is enou-

gh time, as dirt accumulates, microorganisms will re-contaminate and grow, and gradually develop into biofilms. We must try to ensure that

cleaning and disinfection are carried out before the biofilm is formed to prevent the formation of biofilms. At the same time, it is also necess-

ary to eliminate or inhibit the important environment for the survival of biofilms-microbial niches.

Water plus food debris, plus a certain amount of time and temperature, the biofilm formed is easy to become the source of food microbial c

ontamination, and microorganisms will directly or indirectly contaminate food.

Unsanitary equipment and facility design and construction, improper operation and unsanitary equipment and facility maintenance and repair

are prone to produce microbial niches, such as insoluble protein and fat debris, cleaning equipment placed in the food processing area, dam-

aged gloves, etc. Therefore, we often say that there are no gaps, cracks, corrosion, crypts, open welds, overlapping welds, notches, protrud-

ing corners, nail holes and dead ends in the equipment and environment. All welds must be continuous and closed. Not only do equipment

manufacturers need to ensure the continuity of welds and the absence of hiding points when manufacturing equipment, but food processors

must also ensure that these requirements are met when maintaining, repairing and modifying equipment.

The focus of biofilm removal is not only on removal, but also on cleaning. Monitoring the food processing environment and ensuring the ratio-

nal design of equipment and factories are the best way to treat both the symptoms and the root causes.

Although biofilms are difficult to remove, they can be removed through eight sanitation steps, which include four washing factors: cleaning

chemical oncentration, temperature, time and mechanical force. As in all aspects of problem solving, there is no panacea that specifically

solves the problem. However, if these eight steps are used in combination with robust monitoring, biofilms can be removed and prevented.

Seven steps of cleaning and disinfection:

01 Dry cleaning

The important thing about the dry cleaning step is to remove proteins on food contact surfaces and remove any garbage or obstacles in the

area that needs to be cleaned. It is critical to disassemble necessary equipment and properly store parts before cleaning to prevent cross

contamination. Disassembly of equipment allows it to be fully cleaned without leaving any dead corners. Identify any internal corners that

may cause microbial infection or "hidin

02 First rinse

Rinse the equipment from top to bottom, using appropriate water temperature and flushing water pressure.03 Use detergent

After the first rinse, the detergent needs to be sprayed on the food contact surface or related cleaning tools. The main function of cleaning

chemicals is to reduce the surface tension of water, so that the dirt is loose and washed away. This step is essential for removing biofilm on

the equipment. Cleaning chemicals help break down any remaining dirt.

• Make sure the foam is properly applied from bottom to top on all equipment.• The foam should be left on the equipment for 10-15 minutes, but do not let the foam dry.

• In this step, the floor of the cleaning area, especially the drainage pipes or floor drains, should be cleaned first.

During the detergent chemical application as well as the hand scrubbing process, it is important to consider four factors:

Concentration

- The concentration of the cleaning chemical should be within the manufacturer's specified use range to effectively help penetrate, break down and remove dirt/debris.

Temperature

- Water temperature affects the effectiveness of decontamination and chemical activation.

Time

- The time required for the cleaning chemical to fully penetrate, break down and remove dirt from the surface.

Mechanical force

- Refers to the optimal water pressure or use of scrubbing tools during the sanitation process to help break down and remove surface dirt. Keep in mind that optimal water pressure may not be available; therefore, concentration, temperature and time must meet the appropriate range to be effective.

It is recommended to rinse all surfaces of foam from the top and work down to the ground. Use high volume/low pressure hot water to remo-

ve all chemicals and dirt. After rinsing, you can use a UV degreasing flashlight to inspect the equipment to verify that the dirt has been remo-

ved.

05 Removal and disinfection

Production, maintenance and sanitation work together to reassemble equipment according to proper sanitation procedures and good manuf-

acturing practices, and use appropriate methods to disinfect after removing condensation and standing water. It should be noted that with the

technical support of professional service providers, appropriate disinfectants should be selected and disinfection steps should be carried out

according to the corresponding SOP.

06 Pre-operation inspection

Before the operation, certain inspections should be carried out, and the cleanliness of the equipment should be verified by means such as

flashlights and sensory inspections. Identify deficiencies or neglected areas in the cleaning process and solve them immediately. Pay special

attention to checking the edges and corners of the facilities and equipment, bend down and look up more often, and use your sense of smell

and vision.

07 Records

Keep relevant cleaning and disinfection records. These records are not only part of a good cleaning and disinfection operation plan, but also

verify the cleanliness of the factory, and ensure compliance with customer requirements and regulatory requirements. There is no one-size-

fits-all solution to prevent biofilm. It requires the cooperation of relevant hygiene plans, professional cleaning and disinfection teams, and

production and maintenance departments to deal with it together.

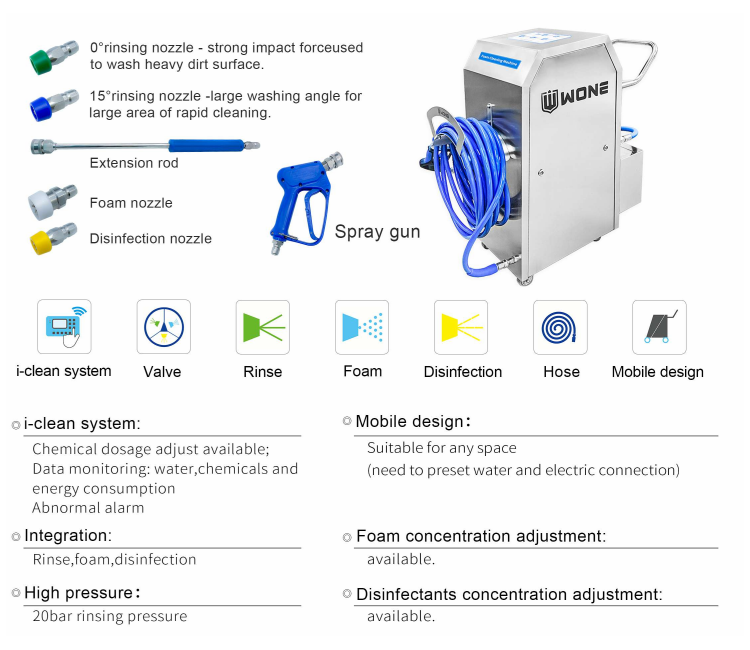

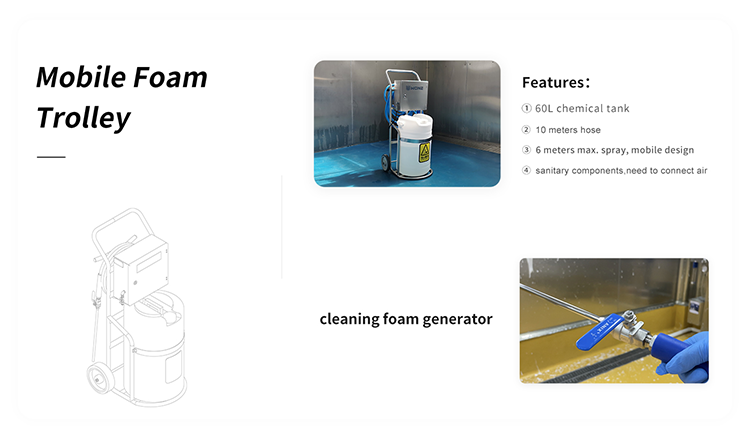

For more knowledge about foam cleaning machines for cleaning and disinfection in food factories, click on the picture below!