From Traditional to Intelligent: The Innovation Road of Food Factory Personnel Sanitation and Cleaning Hygiene Stations

In the food processing industry, personnel hygiene is a key line of defense to ensure food safety. With the rapid development of science and

technology, food factory personnel hygiene and cleaning stations are undergoing a profound transformation from traditional models to intelli-

gent ones. This transformation not only improves cleaning efficiency, but also fundamentally strengthens food safety assurance.

Traditional methods

Historically, food factory hygiene and sanitation practices are mainly manual and labor-intensive. Traditional hygiene sanitation stations usu-

ally consist of basic hand-washing sinks and boot-washing and disinfection sinks. In the hand-washing process, the faucet is usually turned

on manually, and the hands are cleaned with ordinary soap or hand sanitizer, and then rinsed with running water. Disinfection is mostly done

by immersion disinfection.

Although these settings are essential for maintaining cleanliness, this traditional model has many limitations.

First, manual operation is prone to cross-contamination. In the process of turning on the faucet and taking soap or disinfectant, the cleaned

hands may come into contact with the contaminated surface of objects again. Secondly, the cleaning process lacks standardized monitoring.

It is difficult to accurately control key parameters such as hand-washing time and disinfection dosage, which depends entirely on the workers

' consciousness and experience, which leads to uneven cleaning results. In addition, the functions of traditional cleaning stations are relativ-

ely single, which makes it difficult to meet the needs of modern food factories for efficient, convenient and intelligent management.

The need for change

With the development of the food industry and increasingly stringent regulations, the limitations of traditional hygiene practices have become

increasingly obvious. Foodborne diseases and contamination incidents have highlighted the urgent need for more effective hygiene solutions

. This demand for improvement has triggered a wave of technological innovation in hygiene stations.

The rise of smart hygiene stations, innovative breakthroughs brought by intelligence

- 1. Automated operation to eliminate cross-contamination

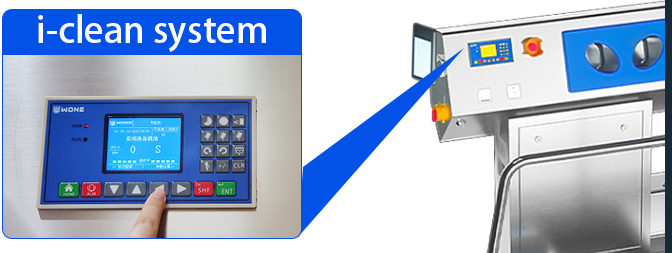

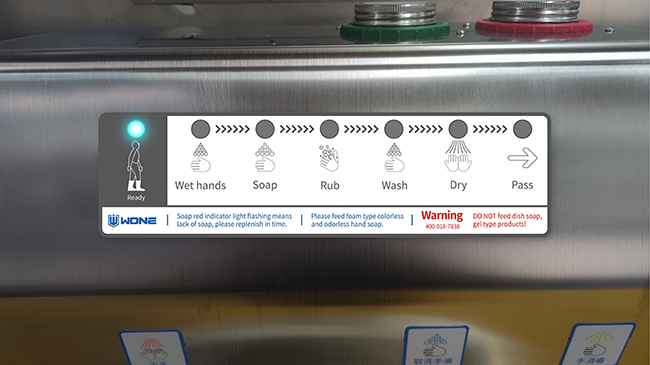

The intelligent personnel hygiene cleaning station introduces advanced sensing technology. The faucet, hand sanitizer and disinfectant disp-

enser all use automatic sensing devices. When the worker's hand approaches, the corresponding equipment automatically starts, avoiding

the cross-contamination that may be caused by manual contact. At the same time, some high-end cleaning stations are also equipped with

automatic hand drying equipment, which uses high-speed airflow or infrared drying technology to completely dry the hands in a short time,

reducing the chance of bacterial growth. In addition, the automated system ensures that all employees follow the same cleaning procedures,

thereby improving overall hygiene standards.

_42712.png)

.png)

- 2. Accurate monitoring to ensure standardized cleaning effects

The intelligent system can accurately monitor and record the key parameters of the cleaning process. For example, the built-in timer can stri-

ctly control the hand washing time to ensure that the workers' hand washing time meets the specified standards and effectively removes bac-

teria from their hands. The dosage of disinfectants can also be controlled by precise metering devices to ensure the consistency of the disin-

fection effect. In addition, the cleaning station can also be equipped with a smart camera to use image recognition technology to monitor wh-

ether the workers' operating procedures are standardized and issue prompt reminders for irregular operations.

- 3. Integrated cleaning hygiene solutions

Modern hygiene stations now integrate multiple cleaning functions into one unit to provide an integrated solution for personnel hygiene. Func-

tions typically include:

- Hand washing stations: These stations are equipped with soap dispensers and hand dryers to ensure thorough cleaning of hands.- Boot cleaning system: Integrated boot washing machines use brushes and detergents to effectively clean footwear, further reducing the

risk of contamination.

- 1. Food safety level

The application of intelligent personnel hygiene cleaning stations significantly reduces the risk of microbial contamination in the food product-

ion process. Through standardized cleaning processes and precise disinfection control, the possibility of pathogens such as bacteria and vir-

uses entering the production workshop is effectively reduced, providing a solid guarantee for food safety. This not only helps companies meet

increasingly stringent food safety regulations, but also enhances consumers' trust in product quality.

- 2. Enterprise management level

The data recording and analysis functions of intelligent cleaning stations provide strong support for enterprise management. Enterprises can

view the use of each cleaning station, workers' cleaning records, and equipment operation status in real time through the backend managem-

ent system. Based on these data, companies can promptly discover management loopholes, optimize cleaning processes, reasonably arran-

ge equipment maintenance and personnel training, and improve overall operational efficiency.

- 3. Industry development level

The intelligent innovation of food factory personnel sanitation and cleaning stations has promoted the development of the entire food industry

in a more modern and intelligent direction. This change not only enhances the competitiveness of food production companies, but also prom-

pts related equipment suppliers to increase R&D investment, continuously innovate and improve products, and form a benign industrial deve-

lopment ecology.

From traditional to intelligent, the innovation path of food factory personnel sanitation and cleaning stations is a vivid embodiment of the deep

integration of science and technology and the food industry. With the continuous advancement of technology, it is believed that future person-

nel sanitation and cleaning stations will be more intelligent, efficient, and humane, escorting food safety and helping the food industry to reac-

h new heights.