How a Boot Washer Ensures Compliance with Food Safety Regulations?

In food production and processing factories facilities, maintaining hygiene compliance is not just a best practice—it's a regulatory necessity.

Among the critical tools for achieving this is the boot washer, a specialized hygiene compliance equipment designed to eliminate contamina-

nts from footwear. With evolving food safety standards, factories increasingly rely on automated boot washers, industrial boot cleaning mac-

hines, and boots integrated washing systems to meet stringent requirements. This article explores how these technologies ensure adheren-

ce to food safety regulations while enhancing operational efficiency.

1. The Role of Footwear Hygiene in Food Safety

Footwear is a common vector for cross-contamination in food processing environments. Dirt, pathogens, and chemical residues on boots

can easily transfer to production areas, compromising product safety. Regulatory bodies like the FDA and HACCP mandate strict protocols

for footwear hygiene to prevent such risks. For example, the food processing plant must ensure food-safe footwear cleaning at entry and

exit points of high-risk zones, such as raw ingredient handling areas or packaging lines.

.png)

.png)

.png)

.png)

.png)

Traditional manual scrubbing methods are prone to human error and inefficiency. In contrast, industrial electric boot cleaners and automated

boot sanitizers provide standardized, repeatable cleaning cycles. These systems use high-pressure jets, cleaning chemical sprays, and bru-

shes to remove debris and pathogens from boot soles and uppers, ensuring compliance with sanitation benchmarks.

2. Key Features of Modern Boot Washing Systems

Modern boots washing machines are engineered to address diverse food factories needs. Below are their defining features:

Automation and Consistency

- Automated boot washers eliminate reliance on manual labor. Workers simply step into the machine, triggering sensors that activate cleaning cycles. This reduces variability and ensures every boot undergoes the same rigorous process.

-

.png)

.png)

.png)

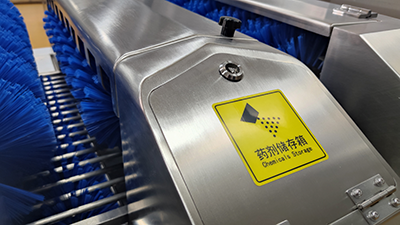

Chemical Integration

- Many systems integrate food-grade disinfectants or sanitizers, such as quaternary ammonium compounds (QACs), to neutralize bacte-ria and viruses. This aligns with regulations requiring the use of approved cleaning agents.

-

Durability and Adaptability

- Industrial boot cleaning machines are built from stainless steel or corrosion-resistant materials, suitable for wet environments. Modular designs allow integration into existing workflows, such as entryways or transition zones between production stages.

3. Compliance with Global Food Safety Standards

Food safety regulations, such as the Global Food Safety Initiative (GFSI) and ISO 22000, emphasize preventive controls. Bootwashers play a

pivotal role in these frameworks by:

Preventing Cross-Contamination

- Pathogens like Salmonella or Listeria can persist on footwear. Automated boot sanitizers cleaning machines with timed disinfectant cyc-les ensure thorough decontamination, reducing the risk of outbreaks.

Documentation and Traceability

- Many industrial electric boot cleaners feature digital logs that record usage frequency, chemical levels, and maintenance schedules. Au-ditors can review these logs to verify compliance during inspections.

-

.png)

.png)

Employee Training Simplification

- Standardized boots integrated washing machines simplify training. Workers need only follow intuitive steps, reducing the likelihood of protocol breaches due to human error.

4. Case Study: Implementing a Bootwasher in a Meat Processing Plant

A poultry processing plant faced recurring contamination issues linked to footwear. After installing hygiene compliance equipment—specifically

, a boots washing machine—the plant observed:

- A 60% reduction in microbial swab test failures.

- Faster transition times between zones, as workers no longer queued for manual cleaning.

- Improved audit scores due to verifiable cleaning records.

- This case underscores how automated boot washers directly correlate with regulatory adherence and operational efficiency.

5. Choosing the Right Boot Cleaning Machine Solution

Selecting appropriate hygiene compliance equipment depends on facility size, workflow, and regulatory requirements. Key considerations inc-

lude:

Throughput Capacity

- High-traffic factories may require boots integrated washing machines with dual chambers to accommodate simultaneous use.

Chemical Compatibility

- Ensure disinfectants used in automated boot sanitizers are approved for food contact surfaces.

Ease of Maintenance

- Opt for industrial boot cleaning machines with self-diagnostic features to minimize downtime.

Innovations in food-safe footwear cleaning are reshaping the industry:

IoT-Enabled Systems

- Sensors in automated boot washers can alert managers to low disinfectant levels or mechanical issues in real time.

Eco-Friendly Solutions

- Newer models use biodegradable cleaners and energy-efficient pumps to align with green manufacturing trends.

Customizable Cycles

- Facilities handling allergens can program bootwashers to include extended rinses, preventing cross-contact.

Conclusion

From industrial electric boot cleaners to boots integrated washing machines, modern sanitization systems are indispensable for meeting food

safety regulations. By automating hygiene protocols, reducing contamination risks, and providing auditable data, these technologies not only

ensure compliance but also enhance overall operational resilience. As regulations tighten and technology advances, investing in hygiene co-

mpliance equipment like automated boot washers will remain a cornerstone of safe food production.

Different types of boot cleaning machines for choice: