How to configure hand washing stations for your food factory?

In the intricate world of food production, where quality and safety are paramount, the unsung heroes of the factory floor are the humble yet

essential hand washing stations. These strategic outposts of cleanliness serve as the first line of defense against the insidious spread of

foodborne pathogens, safeguarding the integrity of the products that nourish communities worldwide.

Hand washing station facilities are the basic hygienic configuration of the food and beverage factories. Although hand-washing facilities have

a single purpose and relatively simple functions, washing hands is the most basic hygiene and cleaning work for food companies. Without

reasonable allocation of hand-washing facilities, there will be a lot of trouble in the future.

We have come into contact with many new food factories, and they often ask what kind of hand washing facilities are the most reliable.

However, the layout and design of different factories are different, so there is no most reliable unified standard. But we would recommend

that food factories refer to relevant laws and regulations to configure hand washing facilities.

According to the SQF (Safe Quality Food) Code, which is a food safety and quality management system standard, there are some

requirements for hand washing that must be followed in food processing facilities.

- Hand washing station must be available and accessible to all personnel in food handling and processing areas.

- These facilities should be equipped with:

- Handwashing basins or sinks

- Hot and cold running water

- Liquid soap dispensers

- Single-use paper towels or air dryers

In response to this, WONE has developed and produced an all-in-one hand washing, drying and disinfection machine, which occupies a

small area, has complete functions and is compatible with all the points mentioned above.

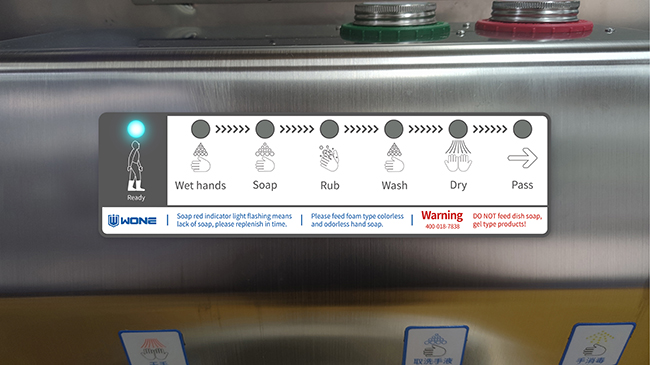

![]() Hand Washing Procedure:

Hand Washing Procedure:

- Personnel must wash their hands thoroughly using the following steps:

- Wet hands with potable water

- Apply liquid soap and create a lather

- Rub hands together for at least 20 seconds, covering all surfaces

- Rinse hands thoroughly under running water

- Dry hands using single-use paper towels or air dryers

Standardized hand washing procedures are critical, and our hand washing facilities display standardized hand washing procedures so that

employees can perform proper hand hygiene according to the instructions.

![]() Frequency of Hand Washing:

Frequency of Hand Washing:

- Employees must wash their hands at the following times:

- Before starting work

- After each visit to the toilet

- After handling contaminated materials

- After sweeping or cleaning

- After smoking, eating, or drinking

- After any other activity that may contaminate the hands

![]() Locations of Hand Washing Station:

Locations of Hand Washing Station:

There are at least 3 places that need to be configured:

- at the entrance of workshop

- Inside the workshop (when needed)

- Toilet

By providing these essential facilities, food processing factories demonstrate their unwavering dedication to food safety and quality control.

The hand washing stations serve as tangible representations of the industry's commitment to upholding the highest standards of cleanliness,

safeguarding the health and wellbeing of both workers and consumers.

For more information about food safety and hygiene machines, please get in touche with us!