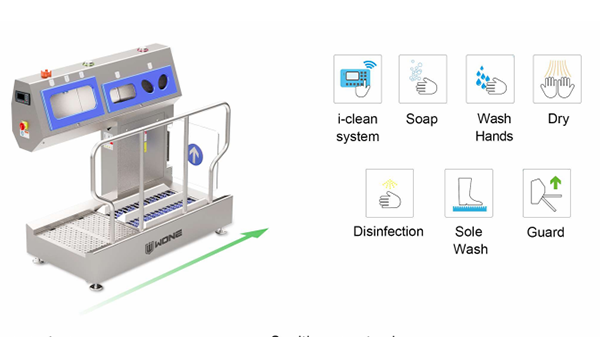

Hygiene Barrier | Sole Brush Hand Washing Drying Disinfection

In the highly regulated world of food production, maintaining impeccable hygiene standards is necessary. Contamination risks loom at every

stage, making entry-point sanitation a critical line of defense. Enter the hygiene barrier—a groundbreaking innovation designed to streamli-

ne and elevate personnel hygiene protocols. Let's explores how this state-of-the-art hygiene barrier integrates multiple sanitization functions

, adapts to diverse environments, and ensures compliance with global food safety standards, all while prioritizing efficiency and durability.

The Hygiene Barrier: Redefining Entry-Point Sanitization in Food Factory

A hygiene barrier is more than a static checkpoint—it's a dynamic system that combines hand washing, drying, disinfection, and sole cleani-

ng into one seamless process. Installed at production workshop entrances, this solution ensures every employee meets stringent hygiene

criteria before accessing sensitive areas. Traditional methods often rely on disjointed stations, creating bottlenecks and compliance gaps. In

contrast, the hygiene barrier eliminates inconsistencies by automating the entire workflow, reducing human error, and guaranteeing thorou-

gh sanitization.

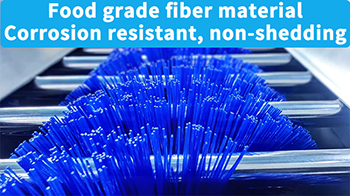

Made of 304 stainless steel, the hygiene barrier withstands harsh industrial environments while resisting corrosion and bacterial buildup. Its

sleek, modular design includes an access door for easy maintenance, ensuring longevity and minimal downtime. But what truly sets this hyg-

iene barrier apart is its intelligent i-Clean system, which customizes hygiene parameters to match facility-specific needs.

Core Features of the Hygiene Barrier

1. All-in-One Sanitization: Efficiency Meets Comprehensiveness

The hygiene barrier consolidates four critical steps into a single unit:

Hand Washing:

- Sensor-activated faucets dispense water and soap at optimal temperatures.

-

_99943.png)

Hand Drying:

- High-speed air dryers eliminate moisture, a breeding ground for pathogens.

-

Hand Disinfection:

- Automated dispensers apply sanitizer at regulated concentrations.

-

Sole Cleaning:

- Rotating brushes scrub footwear, removing debris and contaminants.

-

.png)

By integrating these functions, the hygiene barrier ensures no step is overlooked. Workers move through the process intuitively, guided by

sensors and prompts, while managers gain peace of mind knowing every individual is thoroughly sanitized.

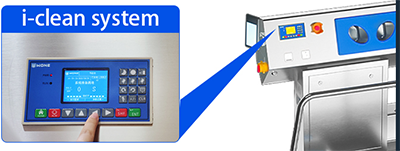

2. i-Clean System: Precision Control for Optimal Hygiene

Main lightspot of the hygiene barrier lies the i-Clean system, a proprietary technology that allows facilities to:

Adjust Hygiene Timers:

- Set minimum durations for hand washing or sole brushing to meet compliance standards.

Regulate Chemical Dosage:

- Automate soap and sanitizer dispensing to prevent waste or underuse.

Monitor Concentration Levels:

- Ensure disinfectants remain effective via real-time adjustments.

Activate Sanitizer Alarms:

- Receive alerts when supplies are low, avoiding disruptions.

This level of customization ensures the hygiene barrier adapts to diverse production environments, whether managing high-throughput facto-

ries or facilities with strict chemical usage policies.

3. Sensor-Driven Automation: Hands-Free Reliability

The hygiene barrier leverages advanced sensors to create a touchless experience. From faucet activation to sanitizer dispensing, every inter-

action is contactless, minimizing cross-contamination risks. This automation not only enhances safety but also enforces protocol adherence—

workers cannot bypass steps without triggering alerts.

4. Modular Design: Flexibility for Any Workspace

Recognizing that no two facilities are alike, the hygiene barrier features a split structure design. Modules can be reconfigured to fit narrow do-

orways or expansive entrances, making it ideal for retrofitting existing sites or scaling new installations. The stainless steel framework is both

lightweight and durable, ensuring quick assembly without compromising sturdiness.

Why the Hygiene Barrier is a Game-Changer for Food Safety

Mitigating Contamination Risks

Human error accounts for over 60% of foodborne illness outbreaks. The hygiene barrier addresses this by standardizing entry procedures. For exa-

mple, a dairy plant in Germany reported a 40% drop in microbial contamination after installing the system, attributing success to its fail-safe design.

Boosting Operational Efficiency

Traditional hygiene stations often cause bottlenecks during shift changes. The hygiene barrier’s streamlined workflow reduces processing time by

30%, allowing employees to enter production zones faster without compromising safety.

Ensuring Regulatory Compliance

Global standards like ISO 22000 and HACCP mandate rigorous hygiene protocols. The hygiene barrier simplifies compliance audits by providing

digital logs of usage metrics, chemical levels, and process completion rates—all accessible via centralized dashboards.

Reducing Long-Term Costs

While the initial investment in a hygiene barrier may seem significant, its durability and efficiency yield substantial savings. Facilities report lower w-

ater and chemical usage due to precise dosing, while reduced contamination incidents minimize recall risks and reputational damage.

Applications Beyond Food Production

Though designed for food factories, the hygiene barrier’s versatility extends to pharmaceuticals, healthcare, and electronics manufacturing—any

sector where contamination control is paramount. For instance, a vaccine production facility in Switzerland uses customized hygiene barriers with

medical-grade disinfectants to meet sterile entry requirements.

Conclusion: The Future of Entry-Point Hygiene

The hygiene barrier represents a paradigm shift in industrial sanitization. By merging automation, adaptability, and intelligence, it addresses the short

comings of traditional methods while future-proofing facilities against evolving safety standards. For food producers seeking to safeguard their produ-

cts, reputation, and bottom line, investing in a hygiene barrier isn’t just prudent—it’s imperative.

In a world where consumers demand transparency and safety, the hygiene barrier stands as a testament to innovation, proving that cutting-edge tech-

nology and uncompromising hygiene can coexist seamlessly.