Hygiene Entrance: Adapt to Any Food Factory Layout

In the food processing industry, maintaining impeccable hygiene standards is non-negotiable. Contamination risks lurk at every corner, and

employee hygiene remains one of the most critical lines of defense. Enter the hygiene entrance—a specialized station designed to ensure

workers adhere to stringent hand and footwear hygiene protocols before entering production areas. As food factories vary in size, workflow,

and layout, a one-size-fits-all approach simply won't suffice. This is where customizable hygiene entrance solutions shine, offering adaptab-

ility to meet the unique demands of any facility.

The Role of the Hygiene Entrance in Food Safety

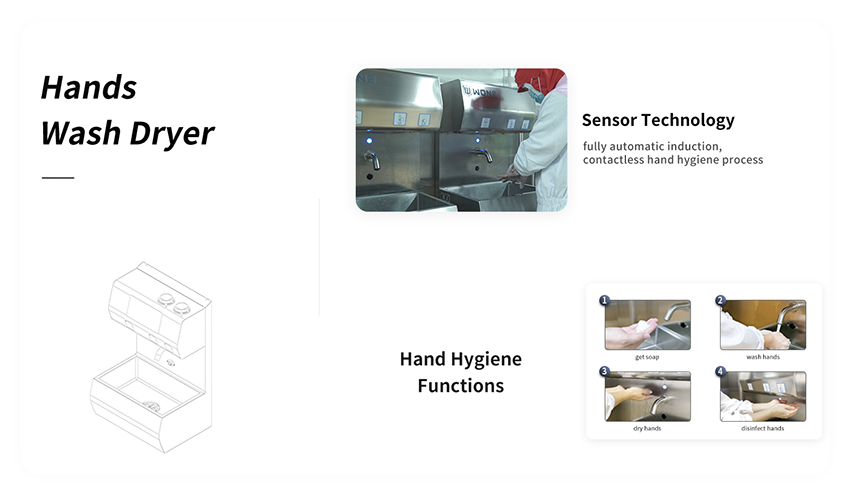

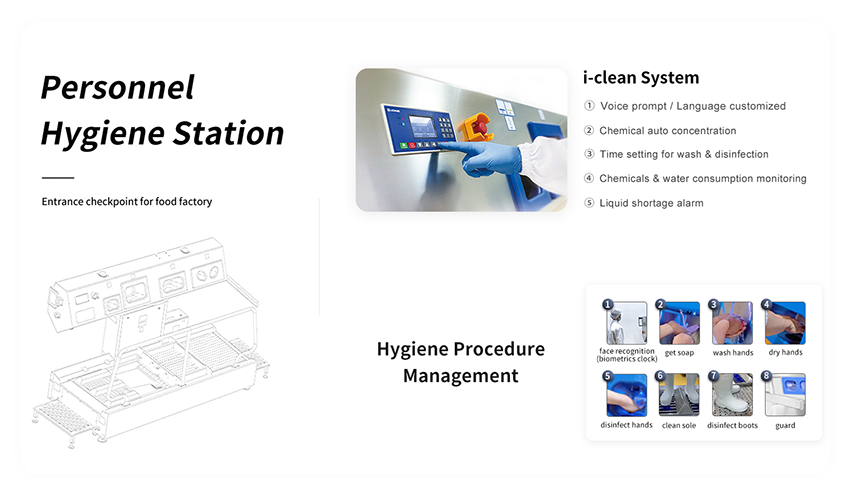

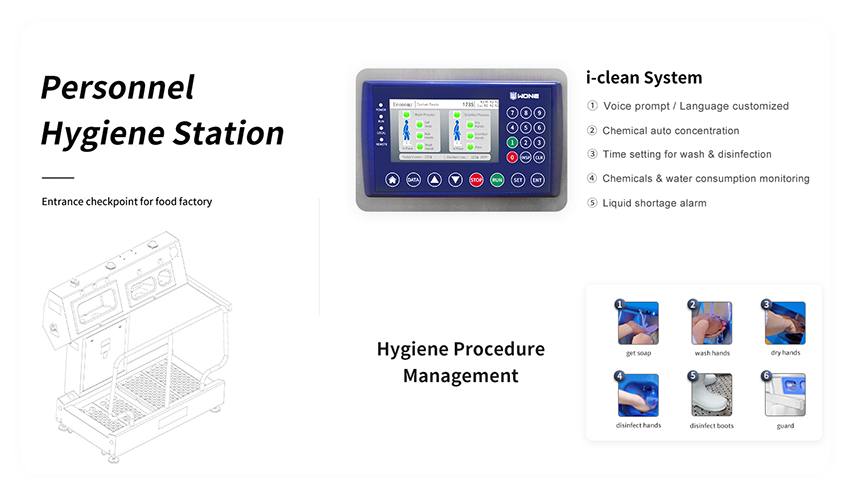

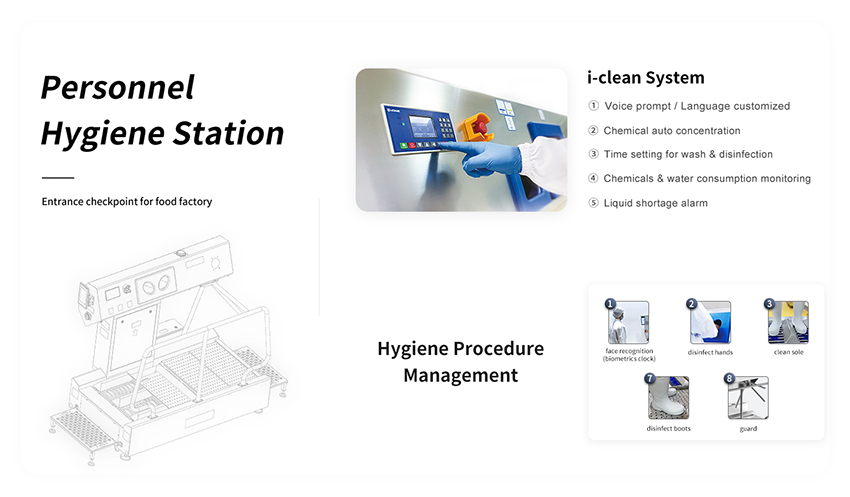

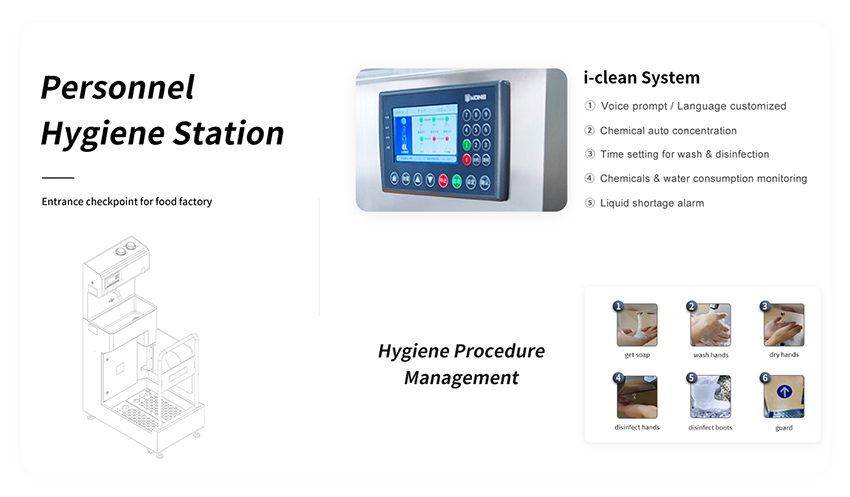

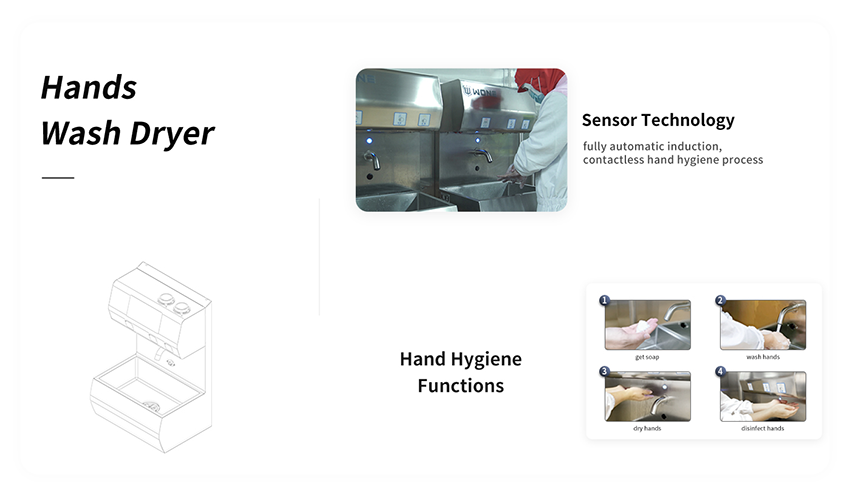

A hygiene entrance serves as the first checkpoint for employees, combining hand washing, sanitizing, drying, and footwear disinfection into

a single, streamlined process. By integrating these steps, facilities reduce the risk of pathogens, allergens, and foreign particles entering se-

nsitive zones. According to the FDA, nearly 48% of foodborne illness outbreaks trace back to poor hand hygiene, underscoring the need for

robust hygiene entrance systems. These stations are not just compliance tools but vital investments in product safety and brand reputation.

Adapting to Diverse Factory Layouts

Food processing plants come in all shapes and sizes—from compact bakeries to sprawling meatpacking facilities. A hygiene entrance must

seamlessly integrate into these environments without disrupting workflow.

1. Space-Saving Designs for Compact Facilities

Smaller factories often face spatial constraints. A modular hygiene entrance with a slim profile can fit into tight entryways, combining hand

hygiene sinks and boot-cleaning pools vertically or horizontally. For example, a single-user hygiene entrance might occupy just 4 square

meters, ideal for facilities with limited floor space.

2. High-Capacity Stations for Large-Scale Operations

In contrast, high-traffic plants require multi-user hygiene entrance stations. These models feature parallel handwashing bays, multiple drying

stations, and extended disinfection pools to accommodate dozens of employees simultaneously. Configurations can be linear, L-shaped, or

U-shaped to align with facility flow patterns.

3. Multi-Zone Facilities and Decentralized Entries

Some factories have multiple production zones, each requiring separate hygiene checkpoints. Here, compact hygiene entrance units can be

installed at each entry point, ensuring compliance without forcing workers to backtrack to a central station.

Customizable Features for Every Need

The versatility of a hygiene entrance lies in its modularity. Facilities can tailor stations based on their specific risks and workflows:

- Hand Hygiene Modules: Options include touchless faucets, antimicrobial soap dispensers, air dryers, and alcohol-based sanitizers.

- Footwear Cleaning: Brush systems, chemical disinfectant pools, or UV light tunnels can be integrated into the hygiene entrance.

- Automation: Sensors and timers ensure employees spend adequate time at each step, while RFID tags can log compliance data.

- Material Durability: Stainless steel construction resists corrosion, and slip-resistant flooring enhances safety.

Single vs. Multi-User Hygiene Entrances

Choosing between single and multi-user hygiene entrance models depends on employee density and shift schedules:

- Single-User Stations: Ideal for small teams or low-traffic shifts, these prioritize space efficiency without compromising functionality.

- Multi-User Stations: Designed for shift changes, these reduce bottlenecks with parallel hygiene stations, cutting downtime by up to 70%.

Compliance and Efficiency Benefits

A well-designed hygiene entrance does more than meet regulatory standards—it boosts operational efficiency. For instance, automated syst-

ems ensure consistent hygiene practices, while ergonomic layouts minimize employee fatigue. Facilities report fewer contamination incidents

and audit non-conformities after implementing tailored hygiene entrance solutions.

Case Studies: Hygiene Entrances in Action

Dairy Plant Optimization

- A Midwest dairy plant reduced glove tears (a common contamination source) by 40% after installing a multi-user hygiene entrance with built-in hand-inspection UV lights.

Snack Factory Upgrade

- A compact hygiene entrance with rapid-dry air knives helped a snack producer adhere to allergen segregation protocols, slashing cros-s-contact risks.

Future-Proofing Hygiene Practices

As food safety regulations evolve, so must hygiene infrastructure. A adaptable hygiene entrance is not just a static installation but a scalable

solution ready to meet tomorrow’s challenges. By prioritizing flexibility, durability, and user-centric design, food processors can ensure their

hygiene entrance remains a cornerstone of their safety strategy—no matter how their facility grows or changes.

Investing in a customizable hygiene entrance isn’t just about compliance; it’s about fostering a culture of safety that protects both consumers

and your brand. Whether your facility is small, sprawling, or somewhere in between, there’s a hygiene entrance solution designed to fit—perf-

ectly.