Hygiene Stations: Hygiene Control at Food Processing Workshop Entrance

In the food processing industry, maintaining impeccable hygiene standards is not just a regulatory obligation—it's a moral imperative. Conta-

mination risks at facility entry points can jeopardize product safety, brand reputation, and consumer trust. Enter hygiene stations: innovative,

non-touch systems designed to fortify hygiene protocols at the first line of defense—the workshop entrance. Let's explores how modern hy-

giene stations are revolutionizing sanitation in food factories, ensuring compliance, efficiency, and peace of mind.

The Critical Role of Entry-Point Hygiene Control

Food processing facilities are high-risk environments where even minor lapses in hygiene can lead to catastrophic outcomes. Pathogens,

dirt, and foreign particles often enter through personal boots, hands, or equipment brought into production areas. Traditional manual cleaning

methods, while functional, are prone to human error and inconsistency. Hygiene stations address these gaps by automating and standardizi-

ng disinfection processes, turning entry points into robust barriers against contamination.

A well-designed hygiene station integrates multiple functions:

- Non-touch hand washing, drying, and sanitizing to eliminate pathogens from workers'hands.

.png)

- Sole cleaning and boot disinfection to remove debris and microbes from footwear.

_89854.png)

- Sanitary-grade construction (stainless steel, corrosion-resistant pipes) to withstand harsh cleaning agents and prevent bacterial buildup.

By centralizing these tasks, hygiene stations streamline workflows while ensuring every individual entering the facility adheres to strict hygiene

protocols.

Anatomy of a Modern Hygiene Station

A state-of-the-art hygiene station is engineered for precision, durability, and ease of use. Let’s break down its core components:

Hand Hygiene Module

- Automatic sensors trigger soap dispensing, water flow, and air drying, eliminating cross-contamination risks.

- Sanitizing misters provide a final protection, neutralizing residual germs.

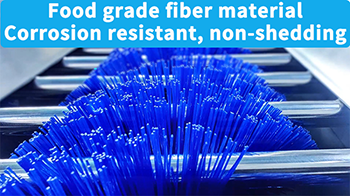

Footwear Cleaning and Sanitization System

- Brush-equipped sole cleaners scrub away dirt, while the disinfection pool to disinfect boot surfaces.

Raised grating allows wastewater to drain efficiently, maintaining a dry, slip-resistant floor.

Rust-proof, food-grade stainless steel ensures longevity and compliance with FDA and HACCP standards.

Seamless welds and rounded edges prevent dirt accumulation, simplifying daily maintenance.

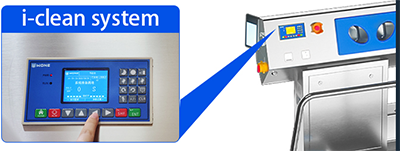

i-clean System Smart Monitoring Features

IoT-enabled hygiene stations track usage data, alerting the lack of cleaning and sanitizing chemical or error.

Manual handwashing stations and footbaths have long been industry staples, but they fall short in critical areas:

Inconsistent Results: Human error leads to incomplete handwashing or rushed boot cleaning.

High Maintenance: Plastic basins degrade quickly, requiring frequent replacements.

Cross-Contamination Risks: Shared towels or door handles undo prior sanitization efforts.

In contrast, hygiene stations deliver:

Uniformity: Automated cycles ensure every employee user follows the same rigorous process.

Durability: 304 Stainless steel components endure heavy use without corrosion.

Labor Savings: Reduced need for supervisory staff to monitor compliance.

A case study from a Saudi Arabian dairy plant revealed a 60% drop in microbial contamination after installing hygiene stations at employee

and delivery entrances.

Meeting Global Hygiene Standards with Hygiene Stations

Regulatory bodies like the FDA, EU Food Safety Authority, and ISO 22000 mandate stringent hygiene controls in food production. Hygiene

stations help facilities comply with key requirements:

GMP (Good Manufacturing Practice): Closed-system sanitization prevents external contaminants from entering production zones.

BRCGS: Automated logs provide auditable proof of hygiene protocols.

FSSC 22000: Stainless steel materials align with sanitary design principles.

For halal-certified facilities, hygiene stations also ensure cleansing processes respect Islamic guidelines, broadening their applicability in dive-

rse markets.

Future Trends: The Evolution of Hygiene Stations

As food safety regulations tighten, hygiene stations are evolving with cutting-edge innovations:

AI-Powered Analytics: Machine learning algorithms predict maintenance needs or identify high-risk entry times.

Biometric Integration: Facial recognition ensures only trained personnel access restricted areas post-sanitization.

Water Recycling: Closed-loop systems reduce water waste by 70%, aligning with sustainability goals.

These advancements position hygiene stations not just as tools for compliance, but as pillars of operational excellence.

Conclusion: Elevate Hygiene, Protect Reputation

In an era where food recalls make headlines and consumer trust is fragile, hygiene stations offer a proactive solution to contamination risks.

By automating hand and footwear sanitization at workshop entrances, these systems empower food processors to safeguard product integrity

, streamline audits, and demonstrate unwavering commitment to safety.

Investing in a hygiene station is more than a capital expense—it's a strategic decision to future-proof operations against evolving threats. As

the adage goes, “Prevention is better than cure,” and nowhere is this truer than in the food industry.