Management of Work Shoes in Food Factory

Management of work shoes in food companies

In the food industry, the management of employees' work shoes is often an issue that food companies tend to overlook but need to pay

attention to. Today, WONE is going to talk about it in this passage.

The user is responsible for the daily use, cleaning, and return of work shoes.

The workshop sanitation staff is responsible for the positioning supervision and sanitation inspection of the work shoes placed in the

changing room.

The workshop supervisor is responsible for daily inspection of the sanitation of work shoes.

02

Employees should place their work shoes on the drying rack in the changing room at the entrance of the workshop and place them in the

designated location according to the number.

Work shoes must not be placed in other places in the changing room at will.

.jpg)

03

Employees put their shoes in the designated place in the locker room

Step 2

Put on special slippers for the locker room

Step 3

Go to the work shoe drying rack, take out the work shoes with the corresponding number, put them on, and put the slippers back in place

Step 4

When entering the workshop, you must disinfect in the shoe and boot disinfection pool at the entrance of the workshop, and the disinfectant

should immerse the shoe surface (the concentration of chlorine disinfectant in the foot disinfection pool is 200-300ppm)

Step 5 Step

You can enter the workshop only after the shoes and boots are disinfected

04

1-Cleaning method

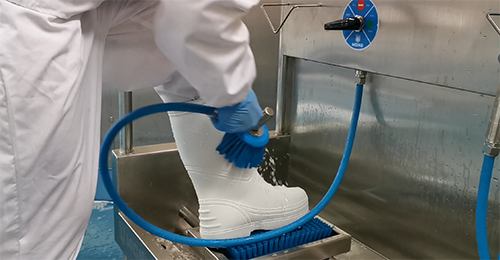

Various areas, such as the surface of work boots, maybe in frequent contact with

animal and plant oils during operation, or be stained with various impurities

Situation

Cleaning method

Rinse--cleaner scrub--rinse--disinfect

Clean area (packaging area, finishing area with less running water on the ground)

scrub--disinfect

Except for the clean area, the ground environment in other areas has less impurities and less water

scrub- -Disinfection

- Scrubbing--Disinfection method

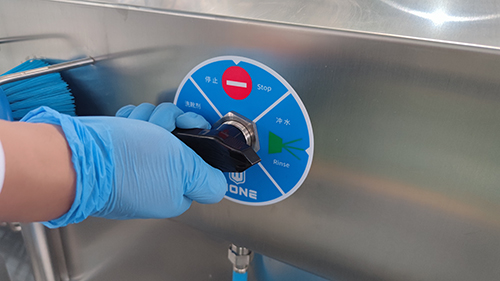

Step 2: Switch the button to the water rinsing, hold the brush, and scrub the sides of the work shoes to remove magazines and stains

Step 4: Change your other foot and follow the steps of 1st-3rd

Step 5: After scrubbing, disinfect boots in the disinfection pool and enter or leave the workshop

- Rinse--Cleanser scrubbing--Rinse--Disinfection method

Step 2: Switch the button to the water rinsing, and use a brush to scrub the sides of the shoes

Step 3: Move your feet lightly and scrape the sides and bottom of the soles of the shoesStep 4: Switch the button to the detergent cleanser button, and use a brush to scrub the sides of the shoes

Step 5: Switch the button to the water wash button, use a brush to scrub the sides of the shoes, and rinse the sides and bottom of the soles

again

Step 6: Change another foot and follow the steps of 1st-6thStep 7: Entrance or leave the workshop after disinfecting the boots in the shoe disinfection pool

2-Cleaning time

Clean regularly after work according to the hygiene requirements of different areas as shown in the table below.

Other times when cleaning is considered necessary

The ground in the working area is often exposed to animal and plant oils,

or is covered with various impurities

Situation

Cleaning method

Frequency

flushing--cleaner scrubbing--flushing--disinfection

every shift

Clean area (packaging area, finishing area with less water flow on the ground)

scrubbing--disinfection

daily

Except for the clean area, the ground environment in other areas has few impurities and less water accumulation

scrubbing--disinfection

weekly

3-After cleaning the shoes

After cleaning the shoes and boots, you should leave the workshop directly. If you still return to the workshop to work, you should wash your

hands and disinfect them again before returning to the site to work.

After leaving the workshop, employees should place their water boots in their own position on the shoe drying rack before leaving the

workshop.

The hygienist checks the placement and cleaning conditions of the work shoes in the locker room at irregular intervals every day and

promptly reminds and corrects any unqualified conditions.

After the hygienist's shift every day, turn on the drying button of the shoe drying rack for timed ozone drying. In case of wet and cold

conditions, the drying time should be appropriately extended. (Since employees wear work shoes for a long time, sweat from the feet will

breed microorganisms or produce odors in the shoes, and the inside of the shoes may be damp due to various external environmental

influences. The hygienist can adjust the drying frequency and drying time appropriately according to the feedback of employees)

The workshop supervisor will check the sanitation and disinfection of work shoes from time to time, and criticize and educate the behaviors

that are not cleaned, disinfected, and placed as required at the morning meeting.

The quality control department will regularly conduct smear spot checks on the sanitation of work shoes in accordance with the relevant

provisions of SSOP. If it is found that it does not meet the relevant sanitation standards, timely measures will be taken. If necessary, the

workshop will organize rectification.

The hygienist cleans and wipes the surface of the shoe drying rack with clean water every week. If there is dirt, stains, etc., it should be

wiped with detergent and then scrubbed with clean water.

The hygienist should observe the use of the shoe drying rack in a timely manner during daily work. If it is found that it is not accurately

returned to the original position or other items are placed on the water boot rack, it should be removed in time and reported to the workshop

supervisor.

The hygienist should observe the operation of the shoe drying rack in time during daily work. If the shoe drying rod is deformed or the serial

number is damaged, the mechanic should be contacted for repair in time.

The workshop supervisor should supervise the use of the shoe-cleaning machine. The shoe-cleaning machine shall not be used to clean

other materials or food contact surfaces.

The hygienist should rinse the surface of the shoe-cleaning machine with clean water every week. If there are dirt, stains, etc., they should

be scrubbed with detergent and then rinsed with clean water.

The hygienist should check whether there are impurities and residues on the scraping brush of the shoe-cleaning machine after the daily

shift. If there are, they should be rinsed immediately.

The hygienist should disassemble and wash the scraping brush on the shoe-cleaning machine every week. The steps include:

Disassembly----rinse with clean water----soak with detergent for 5 minutes----rinse with clean water----soak with disinfectant for 10

minutes----rinse with clean water.

For more knowledge about food factory safety and hygiene, please drink and communicate with us.