Necessary Food Factory Cleaning Safeguards Food Safety

In the global food industry, safety is paramount. Each year, millions fall ill due to contaminated products, underscoring the critical role of food

factory cleaning in protecting public health. Beyond regulatory compliance, rigorous hygiene practices are a moral imperative for manufactu-

rers. This article explores how systematic food factory cleaning—spanning personal hygiene, workshop sanitation, and advanced technology

—forms the backbone of safe food production.

1. The Foundation: Personal Hygiene in Food Factory Cleaning

Food factory cleaning begins with the human element. Workers are both assets and potential contamination risks.

Hand Hygiene: The First Line of Defense

.png)

- 01-Automated handwashing stations with timed scrubbing and antimicrobial soaps.

- 02-Sanitizing at entry/exit points and workstations.

- 03-Training on WHO's 6-step handwashing technique.

Regular audits ensure compliance, integrating hand hygiene into daily food factory cleaning routines.

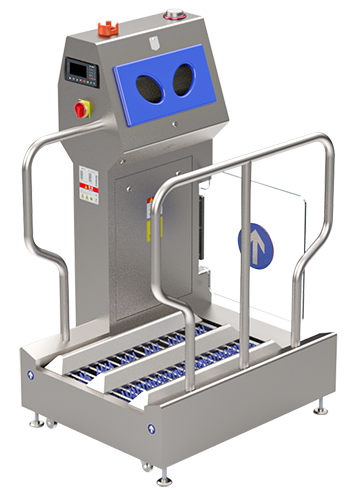

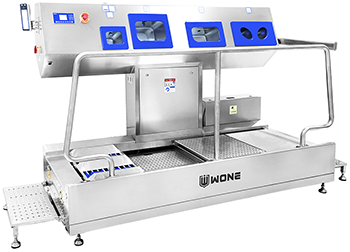

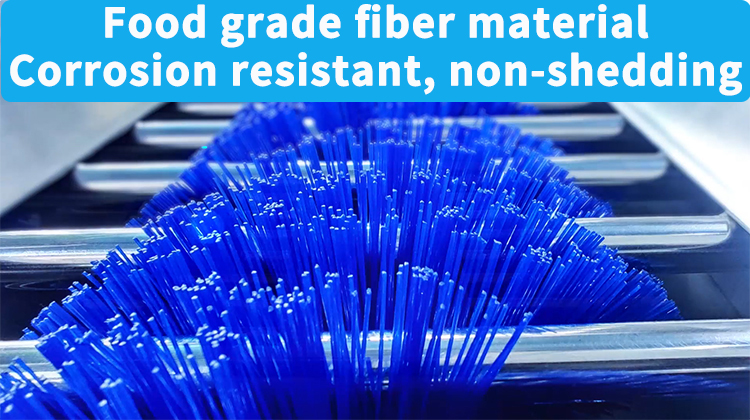

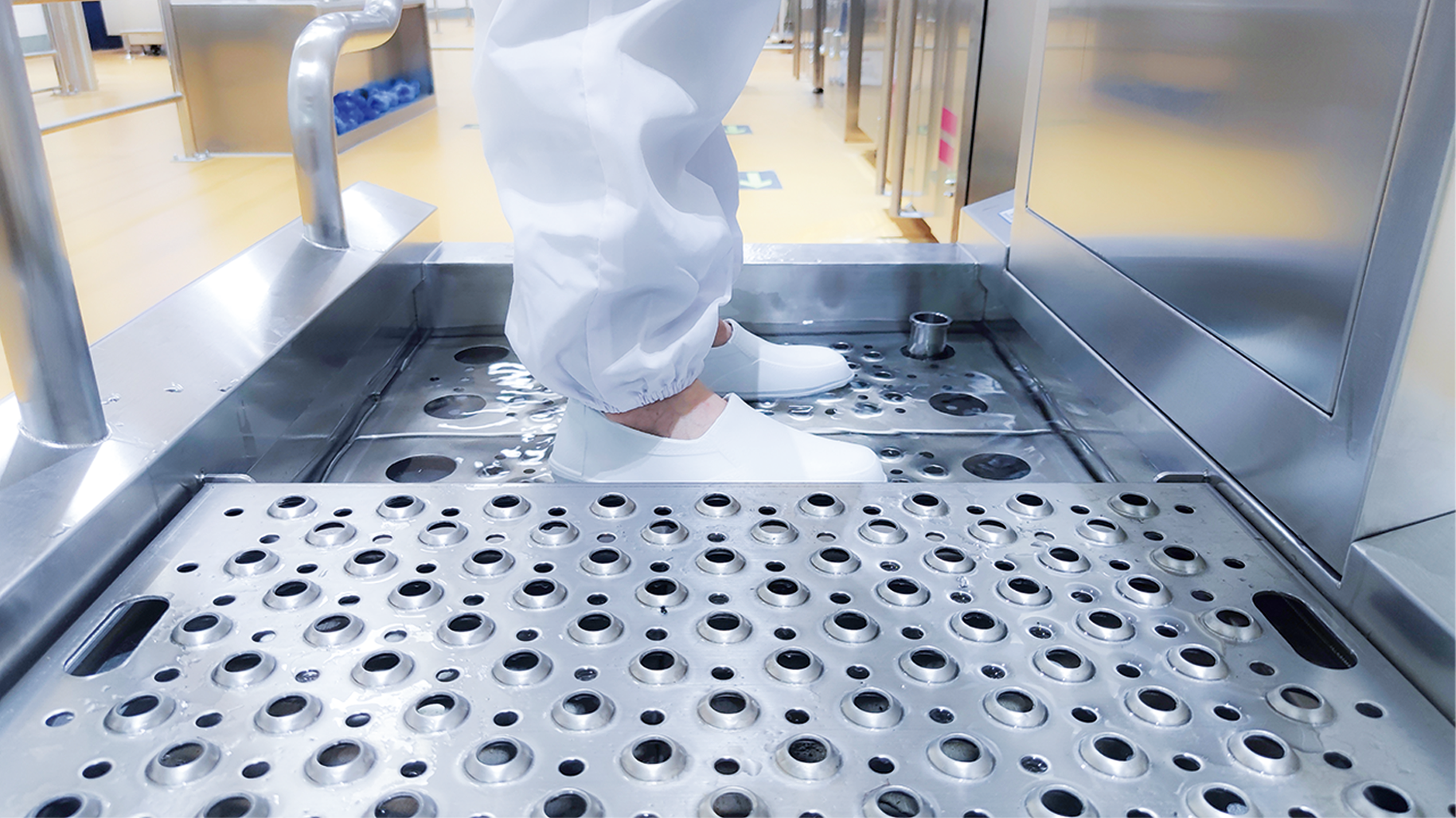

Boot Cleaning: Barrier Against Contamination

.jpg)

- 01-Boot scrubbers and sanitizing baths at facility entrances.

- 02-Color-coded footwear zones to prevent cross-contamination.

- 03-Deep-cleaning protocols for boots used in high-risk areas.

The workshop's open environment demands meticulous food factory cleaning to avoid microbial hotspots.

Equipment Sanitation: Processors and Conveyors

Residues on machinery can harbor bacteria. Key practices:

- 01-Daily dismantling and cleaning of processors using food-grade detergents.

- 02-Conveyor belt cleaning and sanitation with cleaning machine during downtime.

- 03-CIP (Clean-in-Place) systems for closed equipment, ensuring chemical cycles reach all surfaces.

Scheduled deep cleans prevent biofilm formation, a critical aspect of food factory cleaning.

Floor and Wall Maintenance: Beyond Surface-Level Care

Floors and walls face spills and splashes. Strategies include:

- 01-Sloped floors with drains to avoid stagnant water.

- 02-Antimicrobial epoxy coatings on walls for easy cleaning.

- 03-Foam-based sanitizers that cling to vertical surfaces.

Daily sweeps and weekly pressure washing uphold food factory cleaning standards.

3. Technology Revolutionizing Food Factory Cleaning

Innovations enhance efficiency and precision in food factory cleaning.

Automation and Robotics

Autonomous floor scrubbers with UV disinfection.

Robotic arms for high-risk zones, reducing human error.

Smart Monitoring Systems

IoT sensors tracking sanitation metrics in real time.

Digital checklists ensuring no step is missed during audits.

These tools embed food factory cleaning into the digital age, boosting consistency.

4. Compliance and Training: Sustaining Excellence

Regulatory adherence ensures food factory cleaning meets global benchmarks like HACCP and FDA FSMA.

Documentation and Audits

Logs of cleaning schedules and chemical usage.

Third-party audits to identify gaps.

Employee Training Programs

Workshops on PPE usage and chemical handling.

Simulations of contamination outbreaks to test protocols.

Investing in education fortifies the human element of food factory cleaning.

Conclusion: A Culture of Cleanliness

Food factory cleaning is not a task but a culture. From handwashing stations to AI-driven scrubbers, every layer of hygiene contributes to

safer food. As regulations tighten and consumer awareness grows, manufacturers must prioritize cutting-edge food factory cleaning solutions.

By doing so, they protect lives, brands, and the future of food.

Let's champion cleanliness—because every sanitized surface is a step toward a healthier world.