Overview of Foam Cleaning System

Open plant foam cleaning machines are an advanced cleaning technology designed to provide efficient, effective, and safe cleaning of production

equipment, surfaces, and facilities in food and beverage manufacturing. These systems leverage the unique properties of foam to deliver a thorough and

targeted cleaning process.

Features of our OPC foam cleaning machines

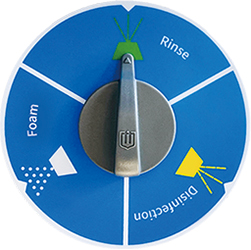

1. Integrated Functions

Our foam cleaning machines combine high-pressure cleaning, foaming, and disinfection functions in one. Maintain a high level of hygiene for food and

beverage factories and reduce the risk of microbial contamination.

2. Efficiency and Effectiveness

Compared to traditional cleaning methods, foam cleaning machine improves cleaning performance and reduces water/chemical consumption.

Firstly, by combining multiple cleaning functions into a single machine, it can potentially reduce the overall water, chemical, and energy consumption

compared to operating separate systems.

On the one hand, our machine can adjust the concentration of foaming. Different concentrations of foam are

adjusted for different levels of grease, dirt, etc., thereby reducing the waste or consumption of chemical agents.

.jpg)

.jpg)

.jpg)

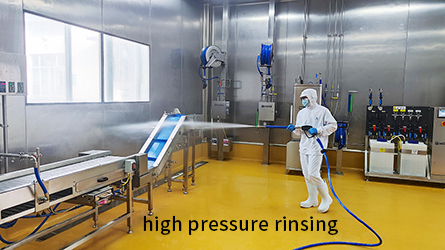

On the other hand, our foam cleaning

machine is a high-pressure rinsing configuration, equipped with 0° and 15° nozzles. 0°rinsing nozzle is with strong impact force used to wash heavy

dirt surface. The 15°rinsing nozzle is a large washing angle for a large area of rapid cleaning. Targeted and effective flushing of stains, thereby reducing

water consumption.

.jpg)

.jpg)

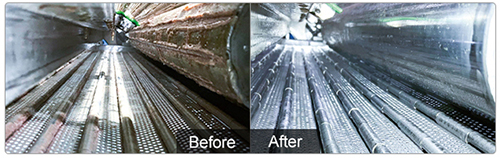

Secondly, foam cleaning reaches hard-to-reach areas and provides a thorough, consistent clean.

On the one hand, for its penetration and coverage,

foam's ability to penetrate crevices, joints, and other hard-to-access regions of equipment, machinery, and production surfaces.

.jpg)

.jpg)

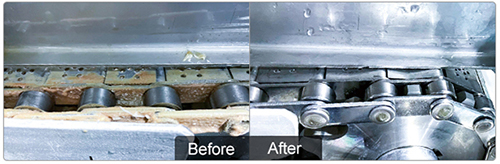

On the other hand, for its cleaning effectiveness, foaming action,combined with the appropriate cleaning agents, can effectively break down and dislodge these tenacious

contaminants. Last but not least. for its consistency and uniformity, the controlled and even distribution of the foam ensures that all targeted areas

receive the same level of cleaning, reducing the risk of missed or inadequately cleaned spots.

.jpg)

WONE's foam cleaning machines are designed to comply with food safety and hygiene regulatory requirements and industry standards such as HACCP

、BRC、SQF etc. Furthermore,

the foam cleaning machine comes with an i-clean system that makes cleaning data or records traceable. Ability to demonstrate compliance during

audits and inspections.

![]()

4.1. Reduced Chemical Consumption:

- Open plant foam cleaning systems often use more concentrated cleaning and sanitizing agents, which can lead to a reduction in overall chemical

consumption.

- The improved coverage and penetration of the foam allows for a more efficient use of the cleaning chemicals, reducing the amount required per

cleaning cycle.

- This can translate to direct cost savings on chemical procurement and inventory management.4.2. Water and Energy Savings:

- Compared to traditional cleaning methods, such as high-volume water rinsing, open plant foam cleaning systems can significantly reduce water and

energy consumption.

- The foam-based cleaning process often requires less water, as the foaming action helps to minimize the amount of rinsing required.- Additionally, the targeted application of the foam and reduced water usage can lead to energy savings in heating, cooling, and water treatment

processes.

4.3. Increased Productivity and Efficiency:

- Open plant foam cleaning systems can streamline the cleaning process, reducing the overall time and labor required.

- The integrated nature of the system, combining multiple cleaning functions (high-pressure, foaming, and disinfection) into a single machine, can lead to

faster cleaning cycles and reduced downtime.

- Improved cleaning consistency and effectiveness can also contribute to fewer production delays or product rejections, further enhancing productivity

and efficiency.

4.4. Extended Equipment Lifespan:

- The thorough and gentle cleaning action of open plant foam systems can help to preserve the condition and extend the lifespan of production

equipment and machinery.

- By effectively removing contaminants and preventing the buildup of deposits, the foam cleaning process can help to minimize wear and tear on critical

components.

- This can translate to reduced maintenance and repair costs, as well as a longer useful life for the equipment.5. i-clean system

The smart system of our foam cleaning solution has the functions below

– chemical dosage adjustment available

– water, chemical consumption monitoring

– abnormal alarm

6. Types of open plant cleaning system

In the dynamic world of food and beverage production, maintaining consistent cleanliness and sanitation across the entire factory is a critical challenge.

Fortunately, the advancements in open plant foam cleaning technology have provided them with a versatile set of solutions to address their unique

cleaning requirements.

For large-scale, complex facilities that require comprehensive cleaning coverage, a decentralized foam cleaning system can be the optimal choice.

These centralized systems integrate multiple foam cleaning stations strategically positioned throughout the production area.

Foam Cleaning Machines:

In facilities with more confined or isolated production areas, stand-alone foam cleaning machines can be an excellent solution. These self-contained

units provide the same powerful foam cleaning capabilities as the decentralized systems but in a more compact format.

Mobile Foam Cleaning Machines:

For food and beverage producers with dynamic production environments or multiple satellite facilities, mobile foam cleaning machines offer a versatile

solution. These portable units can be easily transported and used to clean different areas or production lines as needed. This flexibility is particularly

valuable for manufacturers that need to respond to changing cleaning demands, such as seasonal product changeovers or temporary production

increases.

7. Customers Cases Show

We are very proud of our many successful implementations of cutting-edge foam cleaning systems. From food processing factories and manufacturing

plants to wine and beverage industries, our cleaning stations have had a transformative impact on hygiene practices across industries.

.jpg)

_98127.jpg)

_25311.jpg)

_55534.jpg)

We are WONE, a food enterprise hygiene service provider

Adhering to the mission of "hygiene for a better life", we take hygiene as the basis, equipment as the guarantee, and management as the carrier to

promote the digitalization of food safety and provide food companies with practical overall hygiene solutions.

You are welcome to contact us for win-win cooperation opportunities.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)