Remove Odors & Sanitize Without Chemicals in Food Factories

Remove Odors & Sanitize Without Chemicals in Food Factories: The Power of Advanced Air Disinfec-

tion Technology

Introduction

In the food processing industry, maintaining pristine air quality is non-negotiable. Lingering odors from ingredients like fish, spices, or ferme-

nted products can compromise both product integrity and worker comfort. Simultaneously, airborne pathogens pose contamination risks that

threaten compliance and consumer safety.

Traditional methods often rely on chemical sprays or masking agents, which would introduce new hazards and inefficiencies.

Enter modern air disinfection machines: a revolutionary air disinfection solution combining ozone and UV technologies to sanitize air and

break down odors without chemicals. This article explores how air disinfection systems from trusted air disinfection machine suppliers and air

disinfection machine manufacturers are transforming food factories into safer, cleaner, and more sustainable environments.

Food factories are faceing the unique challenges. Airborne microbes from raw materials or human activity can settle on surfaces or products,

risking spoilage and recalls. Meanwhile, persistent odors from processing stages (e.g., cooking, curing, or fermentation) are more than a nuis-

ance—they signal organic compounds that may attract pests or signal poor hygiene to auditors.

Traditional fixes—chemical fogging, ionizers, or fragrance dispensers—merely mask problems or introduce toxins. In contrast, air disinfection

equipment like UV air disinfection units and disinfection air cleaning units address root causes. These systems leverage:

Ozone (O₃): A natural oxidizer that breaks down odor-causing molecules.

UV-C Light: A proven sanitizer that destroys 99.9% of airborne pathogens.

How Ozone and UV Work in Harmony?

01-Ozone

- The Chemical-Free Odor Eliminator

-

.png)

.png)

Ozone generators in air disinfection devices release controlled amounts of O₃, a molecule that neutralizes volatile organic compounds (VOCs)

and sulfur-based odors at the molecular level. Unlike masking agents, ozone leaves no residue, making it ideal for facilities prioritizing chemi-

cal-free air disinfection systems.

Key Benefits:

- Eliminates stubborn odors from fish, meat, spices, and waste.

- Reduces reliance on aerosol sprays or toxic cleaners.

- Operates efficiently in unoccupied spaces (e.g., after work).

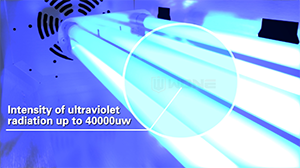

02-UV-C Light

- The Pathogen Destroyer

-

UV air disinfection units use short-wavelength ultraviolet light to disrupt the DNA of bacteria, viruses, and mold spores. When integrated into

ceiling-mounted air disinfection or wall-mounted air disinfection systems, UV-C lamps provide continuous sanitization in occupied or high-traffic

zones.

Key Benefits:

- Prevents cross-contamination in production lines.

- Enhances compliance with HACCP, FDA, and Global Food Safety Initiative (GFSI) standards.

- Works silently, requiring minimal maintenance.

Tailored Solutions for Every Plant

Not all food factories are the same. A poultry plant battling ammonia odors requires different settings than a bakery managing flour dust. Leading

air disinfection machine manufacturers offer customizable air disinfection units to match diverse needs:

1. Wall-Mounted Air Disinfection Systems

Compact and space-saving, these wall-mounted air disinfection devices are ideal for smaller processing areas or zones requiring targeted odor

control. They blend seamlessly into busy environments without disrupting workflow.

.png)

.png)

.png)

.png)

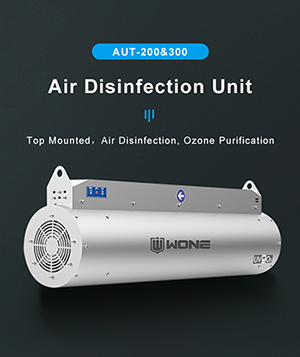

2. Ceiling-Mounted Air Disinfection Units

For large-scale facilities, ceiling-mounted air disinfection systems provide broad coverage, sanitizing air as it circulates through HVAC systems.

This setup is perfect for high-ceiling spaces like packaging halls or cold storage rooms.

.png)

.png)

.png)

Advanced UV air purifier ozone combinators offer dual-action sanitization. For example, UV lamps run continuously during shifts, while ozone

cycles activate after work for deep odor removal.

Why Choose Professional-Grade Air Disinfection Equipment?

While consumer-grade “air purifiers” may promise similar benefits, industrial air disinfection machines are engineered for rigor:

- Durability: 304 Stainless steel withstands humidity, temperature swings, and washdowns.

- Precision or Adjustment: Adjustable ozone output and UV intensity cater to specific contamination levels.

- Certifications: Units are tested to meet ISO 13485, CE, or UL standards, ensuring safety and efficacy.

Partnering with a reputable air disinfection machine supplier ensures access to technical support, compliance documentation, and scalable soluti-

ons as your facility grows.

Case Study: From Odor Complaints to Zero Contamination

A dairy plant in Europe faced recurring odor complaints from nearby residents and failed audits due to airborne yeast contamination. After install-

ing ceiling-mounted air disinfection equipment with UV and ozone functions, the facility reported:

- 90% reduction in odor-related grievances within 4 weeks.

- No positive pathogen swab tests in 6 months.

- Improved employee morale due to fresher air.

Sustainability Meets Cost Efficiency

Chemical-free air disinfection systems align with global sustainability trends. By eliminating toxic sprays, factories reduce their environmental foot-

print while cutting costs on disposable PPE and hazardous waste disposal. Moreover, air disinfection machines have low energy consumption—a

typical UV air disinfection unit uses less power than a refrigerator.

Future-Proofing Your Food Factory

As food safety regulations tighten, proactive adoption of air disinfection technology positions facilities as industry leaders. Emerging innovations,

such as IoT-enabled air disinfection devices with real-time air quality monitoring, further enhance transparency and compliance.

Choosing the Right Air Disinfection Machine Supplier

When selecting an air disinfection machine manufacturer, prioritize partners who:

- Offer free site assessments to design tailored air disinfection solutions.

- Provide clear data on ozone safety thresholds and UV efficacy.

- Supply modular systems for easy expansion.

In an industry where air quality directly impacts safety, compliance, and brand reputation, air disinfection machines are no longer optional—they're

essential. By integrating ozone and UV technologies into wall-mounted air disinfection or ceiling-mounted air disinfection systems, food factories

achieve chemical-free odor removal and pathogen control, all while boosting efficiency and sustainability. Partner with a trusted air disinfection

machine supplier today to future-proof your facility and safeguard what matters most: your products, people, and customers.