SOP for Entering Workshop in Food Factory

I. Personnel should be cleaned and disinfected before entering the workshop

1. The human body is a "natural carrier" of microorganisms

There are a large number of various microorganisms on the surface of the human body, such as skin, hair, oral cavity, nasal cavity and resp-

iratory tract. For example, bacteria such as staphylococci and streptococci are often attached to the skin, and Staphylococcus aureus may b-

e hidden in the nasal cavity. These microorganisms are in a relatively stable state under normal human life, but once personnel enter the foo-

d workshop without cleaning and disinfection, as the personnel walk and operate, the microorganisms can easily fall off and contaminate foo-

d, food processing equipment and packaging materials.

2. Microorganisms endanger food quality and safety

Food, especially processed food, contains rich nutrients, such as protein, sugar, fat, etc., which provide an excellent "hotbed" for the growth

and reproduction of microorganisms. For example, dairy products, pastries, meat products, etc., even if only a small amount of microorganis-

ms are brought into the food, under suitable workshop environmental conditions such as temperature and humidity, the microorganisms may

rapidly multiply in large numbers, causing the food to deteriorate and rot, making it lose its original edible value, and may also cause foodbo-

rne diseases, causing serious harm to the health of the eater.

3. Ensure the effective operation of the quality system

Most food production companies will establish quality management systems such as ISO 22000 food safety management system and HAC-

CP (Hazard Analysis and Critical Control Point) system. In these systems, personnel hygiene management is an indispensable and importa-

nt link. Only by ensuring that the cleaning and disinfection procedures are strictly implemented before the sanitation personnel enter the wo-

rkshop can the entire quality system be guaranteed to operate smoothly, so as to continuously and stably produce food products that meet

the safety and quality requirements, and ensure the competitiveness of the company's products in the market and the rights of consumers.

II. High standards for cleaning and disinfection of high-cleanliness workshops

In food processing plants, particularly in meat processing facilities and ready-to-eat (RTE) bakery processing areas, maintaining high hygie-

ne standards is paramount. These environments are susceptible to contamination, making it essential for personnel to be thoroughly clean-

ed and disinfected before entering the workshop.

III. Process of cleaning and disinfection before entering the workshop

In modern production fields, such as food processing, there are workshop environments with extremely high hygiene standards. In order to

ensure food quality, prevent contamination, and maintain the safety and stability of production, personnel must strictly follow a set of stand-

ardized and detailed cleaning and disinfection processes before entering these workshops. Let's have a deeper understanding of its various

links and significance.

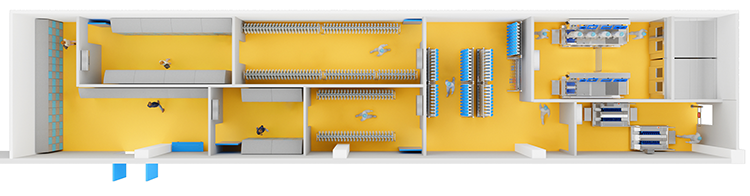

1. Locker room area

Near the entrance of the high hygiene standard workshop, there is a special dressing and preparation area. This area is well-planned, clean

and tidy, and well-ventilated, aiming to provide employees with an orderly preparation space.

The first thing employees should do is to place all personal items, such as mobile phones, wallets, keys, jewelry, etc., in designated lockers.

These items are easily contaminated with various dust and microorganisms in daily use. If brought into the workshop, they will undoubtedly

become a potential source of pollution, so they must be properly stored to ensure that they will not follow employees into the workshop.

3. Dressing regulations

Change of work clothes

The next step is to change clothes. Work clothes are the first line of defense to ensure the hygiene of the workshop. Their materials are care-

fully selected and generally have anti-static, easy to clean, and not easy to pilling and dandruff. Employees should first take off their daily clo-

thes, and then change into clean and well-fitting work clothes in an orderly manner. During the change process, you need to pay attention to

the details of wearing work clothes, such as zipping up and buttoning, ensuring that the collar, cuffs, trouser legs and other parts fit tightly, le-

aving no opportunity for external pollutants, and preventing dust, hair and other impurities from entering the workshop through the gaps.

Wearing protective equipment

Depending on the specific nature and requirements of workshop production, employees need to further wear corresponding protective equip-

ment.

- Head protection: Wear a special work hat, which is designed to completely cover the hair. Both male and female employees should keep all

their hair in the hat to prevent hair from falling and polluting the workshop environment. For some workshops with extremely high requireme-

nts for cleanliness, the hat may also be equipped with a strap to ensure more stability.

- Facial protection: Wear a mask that meets hygiene standards. The mask should fit the face tightly, cover the mouth and nose, and prevent

droplets, exhaled water vapor, and possible microorganisms from spreading into the workshop air. This is especially important in places such

as pharmaceutical production.

- Hand protection: Choose to wear appropriate gloves according to needs. For example, food processing workshops often use disposable fo-

od-grade gloves, and pharmaceutical manufacturing workshops may use sterile latex gloves. Gloves can not only prevent the hands from dir-

ectly contacting the product and causing contamination, but also protect the employees' own safety to a certain extent.

- Foot protection: Wear special work shoes or shoe covers. Work shoes are usually easy to clean and disinfect, and the soles are non-slip an-

d wear-resistant. Shoe covers are more focused on one-time use to prevent dirt and germs carried by the soles of the outside world from ent-

ering the workshop. The choice of the two depends on the specific regulations of the workshop and the actual production situation.

4. Thorough cleaning

Handwashing cleaning

After changing clothes, the cleaning process officially begins, and hand cleaning is one of the core steps. Employees need to move to a sink

equipped with running water and wash their hands in a scientific and rigorous way.

.png)

.jpg)

.png)

Generally, the soles of shoes and boots are cleaned with a channel-type boot washer cleaning machine.

Hand disinfection

After cleaning, the key disinfection step follows, starting with hand disinfection.

- Use disinfectant hand sanitizer: Select a disinfectant hand sanitizer that meets the hygiene standards of the industry where the workshop is

located, and apply the hand sanitizer evenly to all parts of the hands again. Let it stay on the hands for a specified time, generally 1-2 minutes

, so that the effective disinfectant ingredients in the hand sanitizer can fully play a role and kill the residual microorganisms. Then rinse it with

clean water (if it is a disposable disinfectant hand sanitizer, no rinsing is required).

_14507.png)

.png)

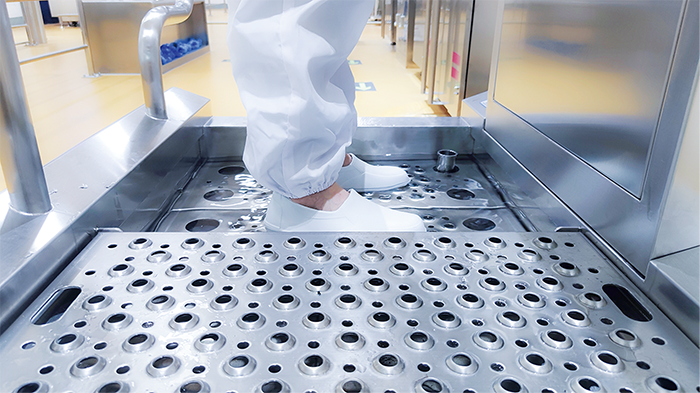

Disinfection of shoes and boots

As the part in contact with the ground, shoes and boots are also prone to carry various germs and pollutants, so they also need to be strictly di-

sinfected. There is usually a shoe and boot disinfection pool at the entrance of the workshop. The disinfection pool will add a disinfectant solut-

ion of appropriate concentration, such as chlorine-containing disinfectant, according to a scientific ratio. When employees enter the workshop,

they need to walk through the disinfection pool and let the bottom and part of the upper of the shoes and boots be fully immersed in the disinfe-

ctant to ensure that the germs carried by the soles and uppers are effectively killed.

6. Air disinfection machine (entry into the workshop passage)

In the passage area leading into the workshop, in order to further reduce the risk of personnel bringing microorganisms into the workshop, ma-

ny workshops are also equipped with air disinfection facilities. Common ones include ultraviolet disinfection lamps. When personnel pass by,

the ultraviolet disinfection lamps will turn on and work, using the bactericidal properties of ultraviolet rays to disinfect and sterilize the air arou-

nd the personnel, reducing the number of microorganisms such as bacteria and viruses floating in the air. In addition, some workshops will

also use air spray disinfection devices to regularly spray disinfectant droplets into the air in the passage to purify the air and create a cleaner

air environment for entering the workshop.

IV. Supervision and guarantee

1. Specialized inspection and supervision

In order to ensure that every employee can meticulously perform the above-mentioned cleaning and disinfection process, the workshop usually

arranges special health supervisors to conduct on-site inspections. These supervisors will carefully check each key link, such as whether the

work clothes are neatly worn, whether the protective equipment is worn correctly, whether the hand cleaning and disinfection meets the standa-

rd requirements, and whether the shoe and boot disinfection is thoroughly in place. Once it is found that an employee does not meet the hygie-

ne requirements for entering the post, the supervisor will promptly urge him to re-perform the corresponding operation until it fully meets the st-

andards.

2. Recording and tracing

At the same time, the company will establish a complete personnel hygiene cleaning and disinfection record system, which records in detail the

specific time when each employee enters the workshop, each cleaning and disinfection step performed, and the information of the person resp-

onsible for supervision. In this way, if there are any hygiene-related problems in the workshop later, these records can be consulted to quickly tr-

ace back to the specific personnel link, accurately check the possible source of contamination, and analyze and evaluate the entire cleaning and

disinfection process based on this, find out the deficiencies and improve them in time, so as to continuously improve the hygiene management

level of the workshop.

These supervisions can be achieved through our intelligent personnel hygiene cleaning station.

拷贝.jpg)

拷贝.jpg)

拷贝.jpg)

拷贝.jpg)

Through the above set of rigorous and standardized cleaning and disinfection processes, the risk of contamination brought by personnel to high

-hygiene standard workshops can be minimized, creating a highly clean, safe and reliable environment for production activities in the workshop,

and effectively ensuring the high-quality output of products and the smooth progress of production operations.