Why Every Food Processing Factory Needs a Hygienic Boot Drying Rack?

The Hidden Costs of Wet Boots in Food Processing

In food processing factories, hygiene is non-negotiable. Yet, one often-overlooked challenge is the presence of wet, odorous boots worn by

employees. Moisture trapped in footwear breeds bacteria, creates slip hazards, and accelerates wear and tear. Enter the hygienic boot dryi-

ng rack dryer—a game-changer combining ozone deodorization, rapid hot-air drying, and industrial durability. This article explores why a bo-

ot dryer with ozone isn't just a luxury but a necessity for modern food factories.

Compliance with Food Safety Standards Starts with Drying Boots

Food safety regulations like HACCP, FDA, and GMP mandate strict hygiene protocols. Wet boots are a breeding ground for pathogens like

Listeria and E. coli, which can contaminate production areas. A boot dryer stand equipped with shoe dryer ozone technology ensures boots

are thoroughly dried and sanitized between shifts. By eliminating moisture and odor-causing microbes, facilities pass audits effortlessly

while protecting their reputation.

A boot dryer rack isn't just about drying—it's a frontline defense against contamination.

Eliminate Odors and Bacteria with Ozone Technology

Traditional drying methods leave boots dry but not sanitized. A boot dryer with ozone solves this by releasing ozone (O₃), a natural oxidizer

that:

- -Breaks down organic matter (sweat, food particles).

- -Neutralizes 99% of odor-causing bacteria.

- -Prevents mold growth in boot linings.

- -Unlike chemical sprays, shoe dryer ozone is residue-free, making it ideal for sterile environments.

Case Study:

A Midwest poultry plant reduced boot-related complaints by 70% after installing ozone-equipped boot dryer stands.

Hot-Air Drying: Speed Meets Efficiency

Time is money in food production. Workers can't wait hours for boots to air-dry. Industrial boot dryer racks use targeted hot air (40–60°C) to

dry a large pairs of boots in under 2 hours. This rapid turnaround:

- -Supports multi-shift operations.

- -Reduces downtime between rotations.

- -Extends boot lifespan by preventing material degradation.

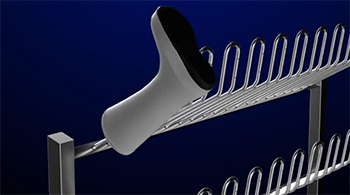

Built to Last in Demanding Environments

Food processing floors are harsh—think humidity, chemical cleaners, and heavy foot traffic. Cheap plastic dryers crack under pressure, but

industrial-grade boot dryer racks feature:

- -Stainless steel or powder-coated frames (rust-resistant).

- -Reinforced shelves for heavy safety boots.

- -IP54-rated components (water and dust resistant).

-

Why It Matters:

A durable boot dryer stand pays for itself by avoiding frequent replacements.

Cost Savings: More Than Just Dry Boots

Wet boots aren’t just uncomfortable—they’re expensive. Consider the hidden costs:

Safety: Slip injuries cost factories $20K+ per incident (OSHA).

Productivity: Workers lose 15+ minutes daily changing damp gear.

Footwear: Moisture ruins $150+ safety boots in months.

A boot dryer with ozone cuts these expenses while boosting ROI.

Facilities save ~$5,000 annually per 50 workers by reducing boot replacements alone.

Employee Comfort Drives Productivity

- -Stay focused instead of battling soggy socks.

- -Avoid fungal infections (e.g., athlete’s foot).

- -Feel valued by employers investing in their well-being.

The Boot Dryer Rack—Your Facility's Silent Guardian

vs

vs

In the high-stakes world of food processing, every detail matters. A hygienic boot drying rack with ozone and hot-air functions isn’t just a

tool—it’s a strategic asset. From ensuring compliance to cutting costs and boosting morale, this equipment delivers unmatched value.

Ready to upgrade? Explore our industrial boot dryer with ozone models today—where hygiene meets efficiency.