WONE Hygiene Station: The Smart Manager of Food Workshop Entrance Hygiene

In the food processing industry, maintaining impeccable hygiene standards is crucial for ensuring product safety and preventing contamina-

tion. The entrance to a food workshop is a critical point where hygiene practices must be strictly enforced. To address this need, we introdu-

ce the WONE hygiene station, a smart solution designed to streamline and enhance hygiene processes at the entrance of food production

facilities. This article will explore the advanced functions of the WONE hygiene station and how it serves as an effective manager of entran-

ce hygiene.

The Importance of Hygiene in Food Processing

The food processing industry faces constant scrutiny regarding hygiene practices. Contaminants can easily transfer from personnel to food

products, leading to serious health risks and costly product recalls. Implementing effective sanitation measures at entry points is essential

for preventing cross-contamination. The WONE hygiene station is designed specifically to address these challenges, ensuring that employ-

ees adhere to stringent hygiene protocols before entering production areas.

Key Functions of the WONE Hygiene Station

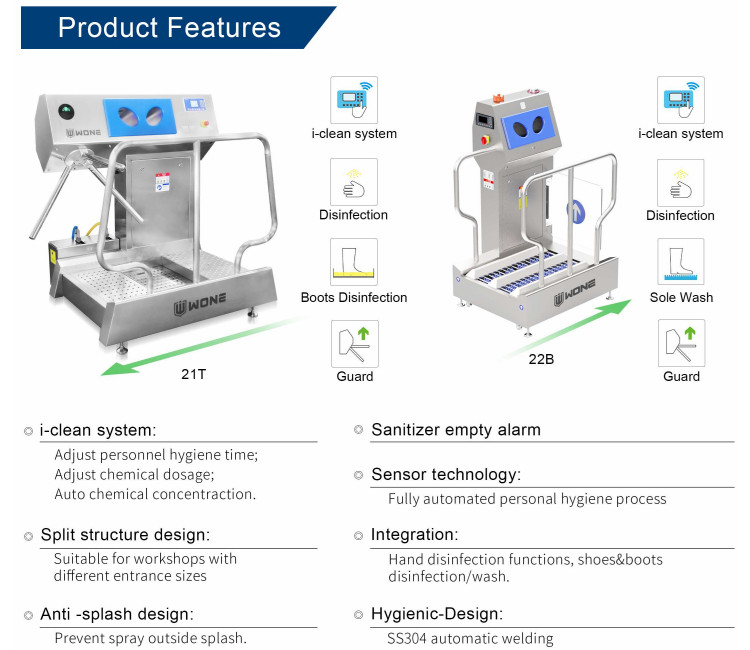

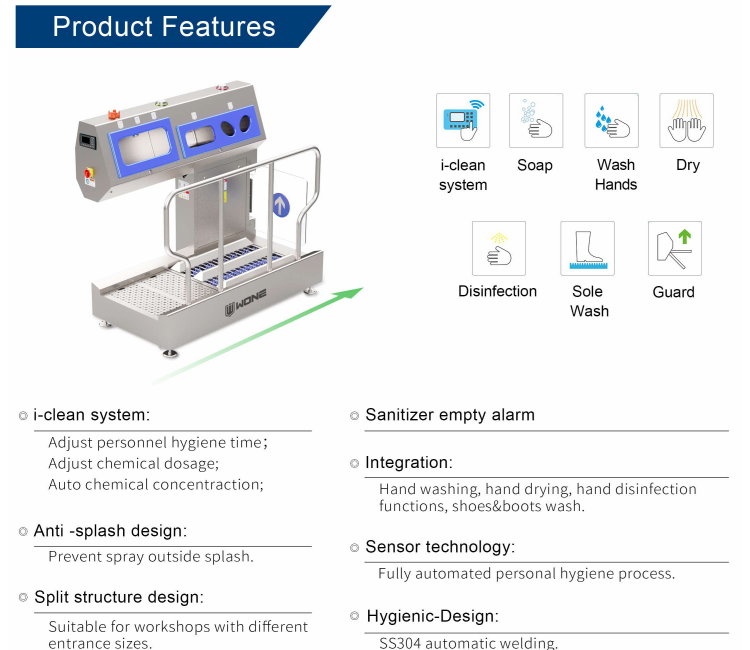

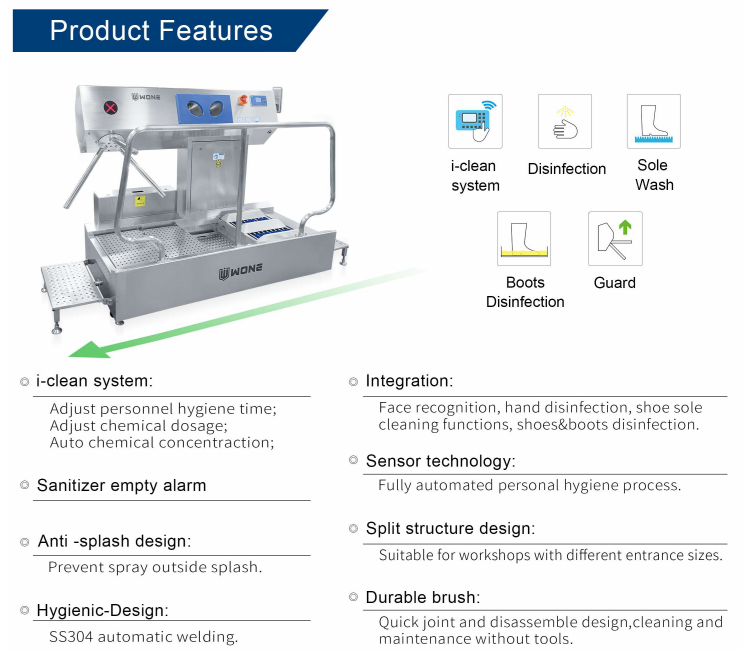

1. Built-in I-Clean System

One of the standout features of the WONE hygiene station is its built-in i-clean system. This advanced technology allows for precise control

over various hygiene parameters:

Adjustable Personnel Hygiene Time: The hygiene station can be programmed to set specific durations for each hygiene step, including

hand washing, hand disinfection, and boot sole cleaning. This customization ensures that employees have adequate time to perform each

task thoroughly, enhancing overall cleanliness.

Chemical Dosage Control: The i-clean system enables adjustment of both cleaning and sanitizing chemical dosages. This feature ensures

that the right amount of solution is dispensed, optimizing the cleaning process while minimizing waste and ensuring the cleaning and disinf-

ection strength.

Auto Chemical Concentration: Maintaining the correct concentration of cleaning agents is crucial for effective sanitation. The hygiene sta-

tion automatically regulates chemical concentration, ensuring consistent performance and effectiveness in cleaning and disinfection.

2. Cleaning and Sanitizing Chemical Empty Alarm

Another essential feature of the WONE hygiene station is its built-in alarm for empty cleaning and sanitizing chemicals. This function alerts

staff when chemical supplies are running low, ensuring that the hygiene station is always ready for use. By proactively managing chemical

levels, this feature helps maintain continuous hygiene operations, preventing lapses that could compromise safety.

3. Hygiene Process Management

The hygiene process management feature of the WONE hygiene station is designed to enforce compliance with established hygiene protoc-

ols. This system includes:

Mandatory Mode: The hygiene station can be set to a mandatory mode, requiring employees to follow specific steps in the hygiene process

. This includes:

- Wet Hands: Employees are prompted to wet their hands thoroughly.

- Take Soap: The station dispenses the appropriate amount of soap for effective cleaning.

- Rub Hands: Employees are guided to rub their hands together, ensuring that all surfaces are cleaned.

- Rinse Hands: The station provides a rinsing function to remove soap and contaminants.

- Air Dry Hands: High-efficiency air dryers ensure that hands are dried quickly and hygienically.

- Disinfect Hands: Finally, the station dispenses a hand sanitizer for additional disinfection.

4. Channel-Style Boot Cleaning and Disinfection

In addition to hand hygiene, the WONE hygiene station features a channel-style boot cleaning system. This design allows for effective clean-

ing and disinfection of work boots as employees enter the workshop. The channel-style setup ensures that all surfaces of the boots are thor-

oughly cleaned, removing dirt and contaminants before personnel access sensitive areas.

Benefits of the WONE Hygiene Station

1. Enhanced Hygiene Compliance

The WONE hygiene station significantly improves hygiene compliance in food processing facilities. By integrating multiple functions into a

single unit, it simplifies the sanitation process and encourages employees to adhere to hygiene protocols. The mandatory mode further reinf-

orces compliance, ensuring that all personnel follow the required steps.

2. Streamlined Operations

With its automated features, the WONE hygiene station streamlines hygiene operations at the entrance of food workshops. Employees can

complete their hygiene routines quickly and efficiently, minimizing downtime and maintaining productivity. The user-friendly design encoura-

ges consistent use, promoting a culture of cleanliness within the facility.

3. Cost-Effectiveness

Investing in the WONE hygiene station can lead to long-term cost savings. By reducing the risk of contamination and potential product recalls

, facilities can protect their bottom line. Additionally, the optimized use of cleaning agents helps minimize operational costs, making the hygie-

ne station a financially prudent investment.

4. Improved Safety and Health Standards

By effectively managing hygiene practices, the WONE hygiene station helps improve overall safety and health standards within food proces-sing facilities. The thorough cleaning and disinfection processes ensure that employees and consumers are protected from potential health

risks associated with foodborne illnesses.

Implementing the WONE Hygiene Station in Your Facility

1. Strategic Placement

To maximize the effectiveness of the WONE hygiene station, it should be strategically placed at all entry points to production areas. This

ensures that every employee has easy access to the station before entering sensitive areas, reinforcing the importance of hygiene.

2. Training and Awareness

Proper training is essential for ensuring that employees understand how to use the WONE hygiene station effectively. Providing training

sessions that cover the operation of the station and the importance of hygiene practices can enhance compliance and promote a culture of

cleanliness.

3. Regular Maintenance

Maintaining the WONE hygiene station is crucial for ensuring its effectiveness and longevity. Regular checks should be conducted to ensure

that all components function correctly, and cleaning agents should be replenished as needed. This proactive approach will help maintain

hygiene standards over time.

Conclusion

The WONE hygiene station is an essential tool for maintaining hygiene at the entrance of food processing facilities. With its advanced featu-

res, including a built-in i-clean system, chemical empty alarm, hygiene process management, and channel-style boot cleaning, this station

serves as a smart manager of entrance hygiene. By investing in the WONE hygiene station, food manufacturers can ensure compliance with

health regulations, enhance product safety, and ultimately protect consumers.

As the food industry continues to prioritize hygiene and safety, the role of effective sanitation solutions like the WONE hygiene station will

only grow. By streamlining cleaning processes and promoting a culture of cleanliness, the WONE hygiene station stands out as a vital asset

in safeguarding public health and maintaining the integrity of food products.